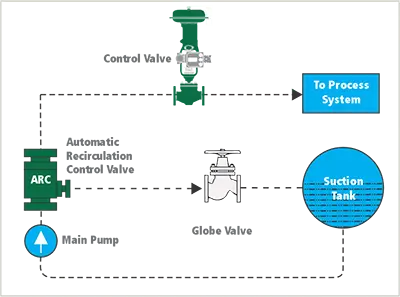

An automatic recirculation control valve is designed to protect centrifugal pumps, especially in systems that handle hot water or other special fluids. It plays a crucial role in preventing issues like cavitation, overheating, vibration, and noise, which can happen when the pump is running at low load. The automatic recirculation control valve ensures the pump doesn't get damaged by controlling the bypass flow and keeping the pump running at its minimum required flow, even under low load or low flow conditions.

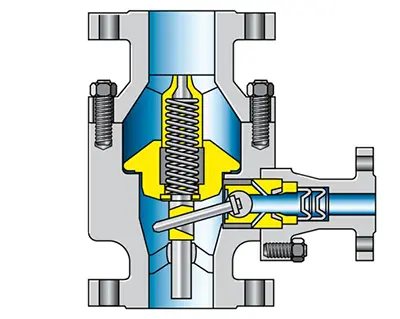

This valve combines several functions in one device. It includes a check valve, flow sensing, bypass control, and multi-stage pressure reduction features. The valve automatically adjusts to match the system's flow needs.

The valve's main job is to adjust itself automatically based on the flow in the main line. When the pump runs at low load or low flow, the valve opens the bypass to ensure the pump gets the minimum flow it needs. This prevents overheating and cavitation. Even if the main flow drops to zero, like when the pump is off or barely running, the bypass still provides enough flow to keep the pump circulating. This ensures the pump keeps running smoothly in all conditions.

The valve's bypass section comes with multi-stage throttling. This helps lower the high pressure from the pump's outlet to a safer level for the return flow system. It prevents cavitation, noise, and damage from high pressure. The bypass flow control ensures the system can handle different flow needs, keeping everything running efficiently.

The valve not only detects changes in flow but also switches between the main flow and the bypass automatically. When the pump's flow drops, the main valve closes, and the bypass opens to keep the minimum flow needed. Once the main valve shuts, the flow goes completely through the bypass and back to the reservoir. During this process, the bypass flow is carefully controlled to reduce both pressure and flow, protecting the pump from too much pressure or flow.

The valve has a compact design, usually using a T-type three-way structure that combines the main flow, bypass, and check valve functions. This lets the valve automatically switch the flow direction when needed, ensuring the pump is always protected.

Main Flow Section: The main flow section includes a check valve to prevent backflow. The main valve adjusts based on the flow to make sure the pump runs properly.

Bypass Section: The bypass section includes multi-stage throttling and pressure reduction features. It provides enough flow when the pump runs at low flow, and reduces the pressure of the return fluid to a safe level. This ensures the pump gets its minimum flow while reducing the load on the pump and preventing cavitation.

No External Power Needed: The valve operates mechanically without relying on any external electrical power. It uses flow sensing to control the valve, making it reliable and safe since there's no risk of electrical failure.

The automatic recirculation control valve offers several important features and benefits that make it a vital part of pump protection systems.

The valve adjusts automatically based on the flow, without needing any electrical power or control systems. This eliminates the risk of electrical failure, ensuring the system stays stable and reliable. It's especially useful in places where power supply is unstable or where electrical systems need to be kept simple.

The valve adjusts the bypass flow to match the system's needs, reducing energy waste even in low-flow situations. It helps keep the pump at its minimum flow while saving energy and improving the overall efficiency of the system.

Because the valve doesn't rely on complex electrical systems, it's easier to maintain. The simple mechanical design means lower maintenance costs. The valve doesn't need frequent maintenance, cutting down on installation, setup, and long-term upkeep costs. This also extends the life of both the pump and the entire system.

The precise control of the main and bypass valves helps prevent issues like backflow, cavitation, overheating, and noise. This reduces the chance of pump damage. The multi-stage throttling and pressure reduction in the bypass also lower the risk of failure due to high pressure or flow.

The T-type three-way structure is compact, making the valve perfect for installations with limited space. It's easy to integrate into existing systems, making installation and maintenance straightforward.

The bypass system slows down the return flow, which reduces noise and mechanical wear. Even after long periods of operation, the valve helps maintain a quiet, stable environment, keeping the system running smoothly.

The valve is commonly used in industrial systems that require stable pump flow. Some of the main industries that use these valves are as follows.

Hot Water Circulation Systems: In hot water pumps that run at low load, the valve ensures the pump maintains the minimum flow needed, preventing overheating and cavitation.

Cooling Water Systems: The valve protects cooling pumps, making sure they provide cooling performance even under low flow conditions, preventing overheating and damage.

Chemical, Petrochemical, and Pharmaceutical Industries: When transporting chemicals or other fluids, the valve prevents pump damage from low flow and ensures the system remains stable and safe.

HVAC Systems: The valve helps adjust flow to keep water pumps running smoothly, avoiding failures or overheating caused by insufficient flow.

The automatic recirculation control valve is an effective, energy-saving device that helps protect pumps from damage, especially during low-flow or low-load conditions. With benefits like self-operated control, low maintenance, and energy efficiency, it ensures that the pump runs smoothly and stays protected at all times. As industries continue to evolve, the valve will play an increasingly important role in protecting pumps, improving energy efficiency, and extending the life of systems. It's a key component in any pump protection setup.