On this page

Pig Launcher & Receiver are crucial components in pipeline systems. They are widely used for cleaning, inspecting, and maintaining pipelines. These devices play a key role in keeping pipelines running smoothly, boosting production efficiency, and lowering maintenance costs. Not only do pig launcher & eeceivers effectively clean pipes, but they can also help separate different products in the same pipeline, making them essential in many industries.

A pigging tool, often called a "pig", is a device used to clean and maintain pipelines. It's pushed through the pipeline by the fluid inside or with the help of compressed air until it reaches the receiver. The main tasks of a pigging tool are as follows.

Pipeline Cleaning: The pig removes deposits, dirt, oil, and other materials that could block the flow of fluid inside the pipeline.

Pipeline Inspection: Smart pigs can check the inside of the pipeline, monitor wall thickness, look for corrosion, and detect other potential issues.

Product Separation: In pipelines carrying multiple products, pigs are used to separate them, preventing cross-contamination and ensuring the quality of each product.

The term "pig" comes from the squealing sound the tool makes as it moves through the pipeline. It uses the fluid pressure inside or compressed air to clean, inspect, and maintain the pipeline, without interrupting its regular operation.

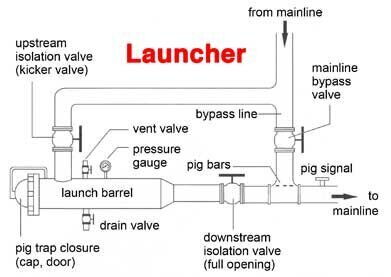

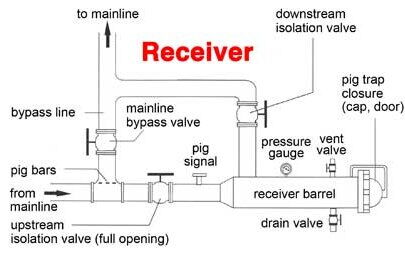

Pig Launcher & Receiver are vital parts of any pipeline system. They consist of a few important parts, like quick-opening blind plates, barrels, reducers, saddles, and various connection pipes (for things like pressure gauges, vents, discharge ports, fluid inlets and outlets, and safety valve connections). Here's a breakdown of their main functions.

The launcher is the device that pushes the pig into the pipeline. It uses pressure—either from the fluid inside the pipeline or from compressed air—to send the pig on its way. The launcher ensures the pig moves smoothly through the pipeline and completes its cleaning, inspection, and maintenance tasks. It usually has a limit stopper that prevents the pig from falling out or getting stuck, ensuring that the pig enters the pipeline correctly and follows the planned route.

The receiver is located at the other end of the pipeline. It catches the pig once it's finished traveling through the pipeline. The receiver uses control valves and pressure regulation systems to ensure the pig arrives safely and is securely placed inside the receiver station. The receiver also stores the pig after the task is completed, ensuring that the system keeps running without interruption. Both the launcher and receiver are equipped with valves, pressure sensors, and safety devices to keep the pipeline system safe and reliable during pigging operations.

The pigging process typically involves a few simple steps.

After the production process ends, the operator first shuts the main feed valve to stop the flow of products in the pipeline.

The limit stopper on the launcher is opened, and the pig is pushed into the pipeline.

For liquid pipelines, the air vent valve is closed, and the intake valve is opened to let compressed air into the launcher.

Compressed air is slowly injected, raising the pressure to a set value (usually no more than 0.2 MPa). This prepares the pig to start its journey through the pipeline.

The airflow is adjusted to keep the pig moving steadily. Too much or too little pressure can cause the pig to lose control or stall.

The receiver introduces compressed air slowly to help the pig move through the pipeline.

The main discharge valve of the receiver is closed, and the vent valve on the intake pipe of the launcher is opened. The compressed air pushes the pig further into the pipeline.

Once the pig reaches the launcher, the limit stopper is closed, securing the pig inside. The pig has now finished its job. It doesn't need to be removed unless maintenance or replacement is required.

Pigging tools are used in a variety of industries. Here are some key applications.

Pigging tools are essential in oil and gas pipelines, especially in long-distance ones. Smart pigs do more than just clean—they also check the condition of the pipeline, monitor wall thickness, corrosion, and potential damage. Regular inspections help identify problems early, reducing downtime and maintenance costs.

In chemical pipelines, pigs help clean pipes regularly to ensure the purity of chemicals and smooth flow. They also prevent cross-contamination between different products, ensuring a continuous process and maintaining product quality.

In food and beverage production, pigging tools are used to clean pipelines and prevent cross-contamination between different food products or drinks. They also help maintain hygiene, ensuring the safety and quality of the final products.

Pigging launchers and receivers are designed to handle high pressure. They need to be strong enough to deal with pressure fluctuations over time. To keep them working well, they require regular inspection and maintenance. Here's what's important.

Valve and Seal Checks: Ensure that all valves, seals, and connections are leak-free and can open and close smoothly when needed.

Pressure System Monitoring: Regularly check pressure gauges and air systems to make sure the pig operates at the right pressure.

Cleaning and Equipment Care: Clean the launcher and receiver regularly to prevent dirt, oil, and other debris from affecting their performance.

Pig Launcher & Receiver are essential in modern pipeline systems. They play a key role in cleaning, inspecting, and maintaining pipelines. These tools are widely used in industries like oil, gas, chemicals, and food production. As technology advances, pigging tools are becoming smarter and more efficient. Regular inspection and maintenance keep them running smoothly, ensuring long-term stability, improving production efficiency, and reducing maintenance costs. This, in turn, helps ensure the safety and reliability of the pipeline system.