The flexibility of a pipeline is a physical concept reflecting the ease of deformation of the pipeline, indicating its capacity to absorb thermal expansion, contraction, and other displacement deformations. Different types of supports will hinder the thermal expansion of the pipeline to varying degrees. Spatial pipelines may experience bending, torsion, shearing, etc. The thrust on the pipeline restraint points also varies significantly due to the deformation of each unit within the pipeline.

During pipeline design, it is essential to ensure that the pipeline has sufficient flexibility to absorb displacement strains while keeping the length of the pipeline as short as possible. In pipeline flexible design, in addition to considering the thermal expansion and contraction of the pipeline itself, additional displacements at the endpoints of the pipeline should also be considered.

The task of industrial pipeline flexible design is to provide the entire pipeline system with sufficient flexibility to prevent the following occurrences due to temperature, self-weight, internal pressure, external loads, restrictions on pipeline supports, and additional displacements at pipeline endpoints:1. Failure of the pipeline due to excessive stress or metal fatigue.

2. Leakage at pipeline connections.

3. Excessive thrust or torque on the pipeline, causing excessive stress or deformation on connected equipment, affecting normal operation.

4. Damage to pipeline supports due to excessive thrust or torque.

1. For complex pipelines, divide them into several simpler shapes such as L-shape, π-shape, and Z-shape, using fixed points for analysis and calculation.

2. When determining the positions of fixed points on the pipeline, ensure that the segments between two fixed points can naturally compensate.

3. Initially, utilize changes in the pipeline's direction to achieve the necessary flexibility, but if space constraints or other reasons exist, other compensators may also be employed.

4. It is strictly prohibited to use stuffing box-type compensators in pipelines carrying toxic or flammable media.

5. When employing π-shaped segments for compensation, it is advisable to place them in the middle of two fixed points.

6. Cold tightening can reduce the thrust and torque of the pipeline on connected equipment or fixed points during operation, but pipelines connected to rotating equipment should not be cold tightened. Pipelines connected to rotating equipment should meet the requirements of stress-free installation. When employing cold tightening for pipelines, the effective coefficient of cold tightening should be set at two-thirds.

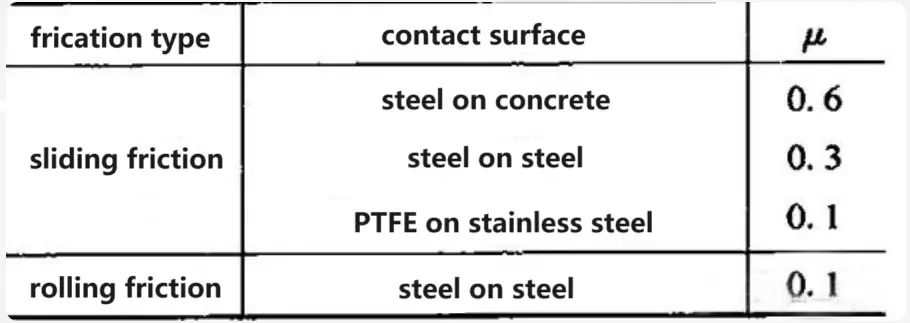

7. In pipeline flexible design, the influence of support friction should be considered, and the friction coefficient should be selected according to the table below.

8. The influence of friction can be disregarded when using hangers or spring hangers to support pipeline loads.

9. In addition to flexible design, reciprocating compressors and reciprocating pump inlet and outlet pipelines should also consider the effects of fluid pressure pulsation (vibration analysis). Reference standards include API 618 for reciprocating compressors and API 674 for reciprocating pumps.

10. Pipeline flexible design includes simplified analysis methods and computer analysis methods. The analysis method should be determined based on design conditions such as the type of equipment connected to the pipeline, operating temperature, and nominal diameter.

11. Both computer analysis and non-computer analysis methods can be used for pipeline design, as detailed in the "SHVT 3041-2016 Petrochemical Pipeline Flexible Design Specification," or other relevant standard specifications.

12. Pipeline flexible design should consider the following dynamic loads:

a. Impact force generated by hydraulic shock, fluid velocity changes, and slug flow;

b. Wind loads on pipelines exposed to the open air;

c. Seismic loads;

d. Reaction forces generated by fluid discharge.

The concept of cold tightening here is not the same as the cold tightening of flange fasteners; rather, it is similar to the cold alignment of large machinery pumps.

Cold tightening refers to a method of generating initial displacement and initial stress in the pipeline during installation (cold state). Cold tightening is typically achieved by shortening the pipeline (applicable when the operating temperature is higher than the installation temperature) or elongating it (applicable when the operating temperature is lower than the installation temperature). The purpose of cold tightening is to distribute a portion of the thermal displacement of the pipeline to the cold state, thereby reducing the thermal expansion stress of the pipeline and the thrust and torque on the endpoints. Cold tightening does not alter the flexibility of the pipeline, nor does it change the range of thermal expansion stress, but it can reduce the forces in the thermal state, hence it is often utilized in designs.

In terms of steel strength, the load-bearing capacity at room temperature is much higher than that at elevated temperatures. Therefore, transferring the thermal deformation of the pipeline to the cold state is advantageous. Thus, pipeline design specifications in various industries stipulate requirements for cold tightening.