2507 stainless steel seamless pipes are a type of duplex stainless steel with a chemical composition of 25% chromium, 7% nickel, 4% molybdenum, and 0.27% nitrogen. This alloy, also known as 2507 stainless steel, exhibits exceptional resistance to pitting corrosion, crevice corrosion, and general corrosion. It combines the best attributes of both ferritic and austenitic stainless steels, making it a versatile and high-performance material. This article explores the composition, corrosion resistance, mechanical properties, and various applications of 2507 stainless steel seamless pipes.

Chemical Composition:

2507 stainless steel, with its distinctive composition of 25% chromium, 7% nickel, 4% molybdenum, and 0.27% nitrogen, falls into the category of duplex stainless steels. This unique blend of alloying elements contributes to its remarkable resistance to corrosion, including pitting and crevice corrosion.

Corrosion Resistance:

General Corrosion: SAF 2507's high chromium and molybdenum content make it highly resistant to organic acids such as formic and acetic acids. It also demonstrates excellent resistance to inorganic acids, especially those containing chlorides.

Intergranular Corrosion: The lower carbon content in SAF 2507 significantly reduces the risk of intergranular corrosion related to carbide precipitation during heat treatment, ensuring strong resistance to this form of corrosion.

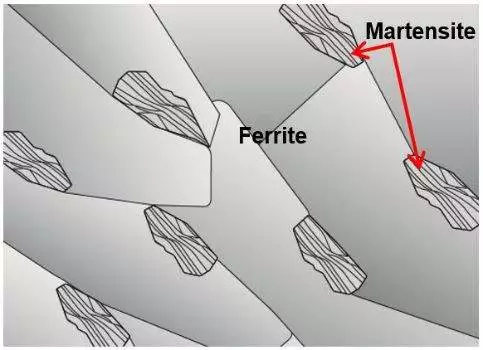

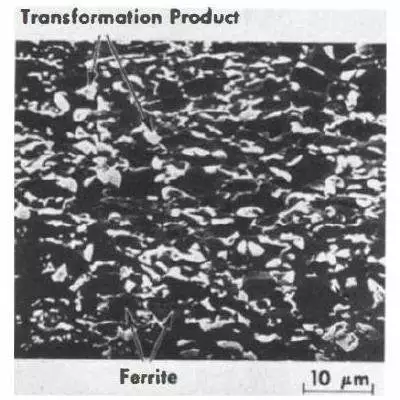

Stress Corrosion Cracking (SCC): The duplex microstructure of SAF 2507 imparts robust resistance to stress corrosion cracking. With its higher alloy content, SAF 2507 exhibits superior corrosion resistance and strength compared to 2205 duplex stainless steel.

Crack and Crevice Corrosion: SAF 2507 demonstrates exceptional resistance to crack and crevice corrosion. In sulfuric acid with 2000 ppm chloride ions, it exhibits a corrosion rate of only 0.1 mm/year. In hydrochloric acid, the corrosion rate remains at 0.1 mm/year, making it reliable in aggressive environments.

Mechanical Properties:

SAF 2507 boasts high tensile strength, impact resistance, lower thermal expansion coefficient, and excellent thermal conductivity. These characteristics make it suitable for various structural components and mechanical parts. It possesses high impact strength, although prolonged exposure to temperatures exceeding 570°F may reduce its toughness. Its tensile strength is σb ≥ 730 MPa, with an elongation rate of δ ≥ 20%.

Welding Consumables:

For welding 2507 stainless steel seamless pipes, ER2594 welding wire and E2594 welding rods are recommended to ensure the integrity of welds and maintain corrosion resistance.

Applications:

2507 stainless steel seamless pipes find applications in various industries, including:

Oil and Gas: Widely used in the petroleum and natural gas industry.

Offshore Platforms: Employed in heat exchanger pipes, water treatment systems, firefighting systems, spray systems, and ballast systems.

Petrochemical Equipment: Used for various components in the petrochemical sector.

Desalination (Desalting) Equipment: Including high-pressure piping in seawater systems.

Mechanical and Structural Components: Suitable for parts requiring high strength and corrosion resistance.

Gas (Waste) Purification Equipment: Due to exceptional corrosion resistance.

Conclusion:

2507 stainless steel seamless pipes, characterized by their dual-phase microstructure, outstanding corrosion resistance, and impressive mechanical strength, represent a significant advancement in stainless steel technology. These pipes have found applications across diverse industries, providing reliable performance in demanding environments. Their resistance to various forms of corrosion, including pitting, crevice, and stress corrosion cracking, makes them a valuable choice for critical applications. Whether in the oil and gas sector, offshore platforms, or chemical processing, 2507 stainless steel seamless pipes offer unparalleled durability and longevity.

For more than 80 years, duplex stainless steels have evolved, with the second generation of duplex stainless steels incorporating nitrogen to enhance their welding and corrosion resistance properties. The flexibility of duplex stainless steels and their ability to bridge the gap between austenitic and ferritic stainless steels make them a compelling choice for a wide range of applications.