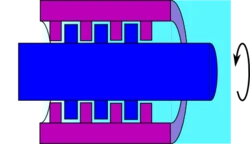

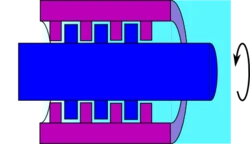

In a labyrinth, a number of circular sealing teeth are arranged around the rotating shaft in sequence, and a series of intercepting gaps and expansion cavities are formed between the teeth. When the sealed medium passes through the gaps of the labyrinth, it produces a throttling effect to achieve the purpose of leakage prevention.

Because there is a gap between the rotor and the casing of the labyrinth seal, there is no solid contact, and lubrication is not required. The thermal expansion is allowed, so it is suitable for high temperature, high pressure and high-speed frequency occasions. This seal form is widely used for the shaft end and stage seal of steam turbines, gas turbines, compressors and blowers, and the front seal of other dynamic seals.

Sealing Mechanism of Labyrinth Seal

The function of generating resistance and reducing the flow through the fluid labyrinth is called the "labyrinth effect". For liquid, there are hydrodynamic effects, including hydraulic friction effect and flow contraction effect; For gas, there is also thermodynamic effect, that is, heat conversion caused by compression or expansion of gas in the labyrinth; In addition, there is "ventilation effect" and so on. The labyrinth effect is the comprehensive reaction of these effects, so the labyrinth sealing mechanism is very complicated.

1. Friction effect: When the leaked liquid flows in the labyrinth, the friction caused by the viscosity of the liquid slows down the flow rate and reduces the flow rate (leakage amount). Simply put, the friction and local friction of fluid along the channel constitute the friction effect. The former is related to the length and cross-sectional shape of the channel, while the latter is related to the bending number and geometric shape of the labyrinth. Generally, when the flow passage is long, the curve is sharp and the tooth tip is sharp. The resistance is large; The pressure difference loss is significant, and the leakage is reduced.

2. Stream contraction effect: As the fluid passes through the labyrinth seam, it will contract due to inertia, and the cross-section of the stream will be reduced. If the orifice area is A, the minimum area of the contracted stream is Cc A, where Cc is the contraction coefficient. At the same time, the velocity of the gas after passing through the hole also changes. If the ideal flow rate is u1, the actual flow rate is smaller than u1, and Cd is the velocity coefficient, then the actual flow rate u1 is u1=Cdu1. Therefore, the flow rate through the hole will be equal to Cc*Cd=a (flow coefficient) in q=CcCdAu1. The flow coefficient of the labyrinth seam is related to the shape of the gap, the shape of the tooth top and the roughness of the wall surface. For incompressible fluids, it is also related to the required number; For a compressible fluid, it is also related to pressure ratio and Mach number. At the same time, it also affects the flow state before the seam. Therefore, in a complicated labyrinth, the flow coefficient of one seam cannot be regarded as the flow coefficient of all seams. According to the test, the flow coefficient of the first stage is smaller, and the flow coefficient of the seam after the second stage is larger. Generally, the flow coefficient is usually 1. However, the flow coefficient of sharp teeth is smaller than 1, about 0.7, and that of round teeth is close to 1, usually taking a=1, so the calculated leakage is large.

3. Thermodynamic effect: an ideal labyrinth channel model, which is formed by connecting annular tooth gaps and cavities between teeth in series. The flow of gas through each tooth gap and interdental cavity can be described as follows: at the entrance of the gap, the state of the gas is p0, T0 and zero. The closer the gas is to the entrance, the more the gas will contract and accelerate. Not far behind the smallest gap, the gas will get the maximum speed: when entering the cavity, the cross-section of the velocity suddenly expands and a strong vortex will be formed in the cavity. From the energy point of view, before and after the gap, the pressure of airflow can be converted into kinetic energy. At the same time, when the temperature drops (enthalpy value H decreases) and the gas enters the circular chamber between the two teeth at a high speed, the volume suddenly expands to produce a violent vortex. As a result of the vortex, most of the kinetic energy of the airflow is converted into heat energy, which is absorbed by the airflow in the chamber to raise the temperature, and the enthalpy returns to the value close to that before entering the gap. Only a small amount of kinetic energy still enters the next gap at the residual speed, thus repeating the above process step by step.

4. Breathing effect: In an ideal maze, it is considered that the kinetic energy of the airflow passing through the slit in the expansion chamber will all become heat energy. That is to say, it is assumed that the asymptotic velocity to the next seam is equal to zero, but this is only true when the expansion chamber is particularly wide and long. Generally, in a straight-through labyrinth, because the airflow passing through the slit can only spread to one side, the energy conversion from velocity energy (kinetic energy) to heat energy cannot be fully carried out in the expansion chamber, while the velocity of a part of the gas near the smooth wall does not decrease or only slightly decreases, and it directly crosses the top of each ten teeth and flows to the low-pressure side, which is called "ventilation effect".

Structure Type of Labyrinth

According to the different structures of seal teeth, the labyrinth can be divided into two types: seal piece and seal ring. The sealing piece has a compact structure, and it collides with the casing during operation. The sealing piece can bend to both sides, reducing friction and being convenient to disassemble and replace.

The sealing ring is composed of 6 to 8 sector blocks, which are installed in the casing and the rotating shaft. Each ring is pressed on the casing by a spring plate with a pressing force of about 60 to 100 N. When the important official collides with the toothed ring, the toothed ring bounces off by itself to avoid friction. This structure is large in size, complicated in processing, and the whole sealing ring is replaced after the teeth are worn, so it is not as widely used as the sealing ring structure.

Leakage Calculation of the Ideal Maze

Given the following conditions:

1. The leaked gas is an ideal gas, regardless of the Jiaol-Thomson effect, that is, the enthalpy of the gas is only related to the temperature.

2. Assuming that the maze is a series of continuous multiple slits, the expansion chamber between the two slits is large enough.

3. The flow through the steam is expanded in adiabatic circulation, and a flow coefficient A is quoted here.

4. The flow velocity energy after passing through the seam is completely recovered at constant temperature in the expansion chamber due to the control of equal pressure, so the velocity before each seam is asymptotically zero, that is, no air permeability occurs.

Characteristics of the Straight-through Maze

Because it is easier to machine grooves or teeth of various shapes on the shaft surface than in 7L, the holes are often machined into smooth ones, which form a labyrinth with the shafts with grooves or teeth. This is the straight-through labyrinth, which is the most widely used because of its convenient manufacture. However, there is ventilation in the straight labyrinth, and its leakage is larger than that of the ideal labyrinth.

Influencing Factors of Labyrinth Characteristics:

1. The influence of teeth. According to the tests conducted abroad, it is concluded that when the tooth pitch is constant, the more the number of teeth is, the less the leakage will be. When the pitch is in a coup, the larger the pitch is, the leakage will drop sharply, and the influence of air permeability can be reduced.

2. Influence of expansion chamber. The influence of expansion chamber depth abroad has been studied experimentally, and the conclusion is that a shallow expansion chamber is beneficial to reduce leakage.

According to the observation of the flow state in the expansion chamber, it is considered that the vortex in the shallow expansion chamber is unstable. Because the vortex can quickly exhaust the energy, the asymptotic velocity of the expansion chamber decreases, which has the effect of reducing leakage.

3. The influence of the auxiliary room. The so-called "auxiliary chamber" refers to the auxiliary groove of the straight-through labyrinth which is smooth and open upward. After the groove is opened, the flow state in the labyrinth changes obviously immediately. The test proves that as long as the position of the auxiliary chamber is appropriate, the reduction rate of leakage is quite large.

Clearance of the Labyrinth Gas Seal

Except in special cases, general turbomachinery such as gas turbines adopt labyrinth gas seals. The radial clearance should be selected according to the following factors: bearing clearance and manufacturing tolerance, error with packing, deformation of parts (such as casting shrinkage and out-of-round), deflection of the rotor, amplitude when passing through critical rotation frequency, thermal expansion and deformation caused by it, etc. In many cases, the influence of thermal expansion is prominent. Therefore, it is necessary to estimate the change in the size of a single component and the relative displacement of the components in advance when starting and stopping. Static and dynamic finite element methods can be used to calculate the time-varying thermal expansion law so that we can know which critical conditions are and how big the gap should actually be.

Points for Attention in Labyrinth Seal Design

Summing up the experience accumulated in labyrinth seal design as follows:

1. Try to convert the kinetic energy of the airflow into heat energy, without the residual velocity entering the next gap. Keep a proper distance from the teeth, or use high-low teeth to change the direction of airflow. The tooth spacing is generally between 5 and 9mm.

2. The sealing teeth should be as thin as possible with acute angles. The thickness of the tooth tip should be less than 0.5mm. When the tooth tip occasionally collides with the shaft during operation, the tooth tip will wear out first and get out of contact, so as not to cause an accident due to local overheating of the shaft due to friction.

3. Due to the large leakage of labyrinth seal, attention should be paid to preventing environmental pollution when sealing flammable, explosive or toxic gases. The inflatable labyrinth seal is adopted, and inert gas is introduced into the gap, the pressure of which is slightly higher than that of the sealed gas. If the medium is not allowed to be mixed with aeration, the air extraction labyrinth seal can be adopted.

Because there is a gap between the rotor and the casing of the labyrinth seal, there is no solid contact, and lubrication is not required. The thermal expansion is allowed, so it is suitable for high temperature, high pressure and high-speed frequency occasions. This seal form is widely used for the shaft end and stage seal of steam turbines, gas turbines, compressors and blowers, and the front seal of other dynamic seals.

Sealing Mechanism of Labyrinth Seal

The function of generating resistance and reducing the flow through the fluid labyrinth is called the "labyrinth effect". For liquid, there are hydrodynamic effects, including hydraulic friction effect and flow contraction effect; For gas, there is also thermodynamic effect, that is, heat conversion caused by compression or expansion of gas in the labyrinth; In addition, there is "ventilation effect" and so on. The labyrinth effect is the comprehensive reaction of these effects, so the labyrinth sealing mechanism is very complicated.

1. Friction effect: When the leaked liquid flows in the labyrinth, the friction caused by the viscosity of the liquid slows down the flow rate and reduces the flow rate (leakage amount). Simply put, the friction and local friction of fluid along the channel constitute the friction effect. The former is related to the length and cross-sectional shape of the channel, while the latter is related to the bending number and geometric shape of the labyrinth. Generally, when the flow passage is long, the curve is sharp and the tooth tip is sharp. The resistance is large; The pressure difference loss is significant, and the leakage is reduced.

2. Stream contraction effect: As the fluid passes through the labyrinth seam, it will contract due to inertia, and the cross-section of the stream will be reduced. If the orifice area is A, the minimum area of the contracted stream is Cc A, where Cc is the contraction coefficient. At the same time, the velocity of the gas after passing through the hole also changes. If the ideal flow rate is u1, the actual flow rate is smaller than u1, and Cd is the velocity coefficient, then the actual flow rate u1 is u1=Cdu1. Therefore, the flow rate through the hole will be equal to Cc*Cd=a (flow coefficient) in q=CcCdAu1. The flow coefficient of the labyrinth seam is related to the shape of the gap, the shape of the tooth top and the roughness of the wall surface. For incompressible fluids, it is also related to the required number; For a compressible fluid, it is also related to pressure ratio and Mach number. At the same time, it also affects the flow state before the seam. Therefore, in a complicated labyrinth, the flow coefficient of one seam cannot be regarded as the flow coefficient of all seams. According to the test, the flow coefficient of the first stage is smaller, and the flow coefficient of the seam after the second stage is larger. Generally, the flow coefficient is usually 1. However, the flow coefficient of sharp teeth is smaller than 1, about 0.7, and that of round teeth is close to 1, usually taking a=1, so the calculated leakage is large.

3. Thermodynamic effect: an ideal labyrinth channel model, which is formed by connecting annular tooth gaps and cavities between teeth in series. The flow of gas through each tooth gap and interdental cavity can be described as follows: at the entrance of the gap, the state of the gas is p0, T0 and zero. The closer the gas is to the entrance, the more the gas will contract and accelerate. Not far behind the smallest gap, the gas will get the maximum speed: when entering the cavity, the cross-section of the velocity suddenly expands and a strong vortex will be formed in the cavity. From the energy point of view, before and after the gap, the pressure of airflow can be converted into kinetic energy. At the same time, when the temperature drops (enthalpy value H decreases) and the gas enters the circular chamber between the two teeth at a high speed, the volume suddenly expands to produce a violent vortex. As a result of the vortex, most of the kinetic energy of the airflow is converted into heat energy, which is absorbed by the airflow in the chamber to raise the temperature, and the enthalpy returns to the value close to that before entering the gap. Only a small amount of kinetic energy still enters the next gap at the residual speed, thus repeating the above process step by step.

4. Breathing effect: In an ideal maze, it is considered that the kinetic energy of the airflow passing through the slit in the expansion chamber will all become heat energy. That is to say, it is assumed that the asymptotic velocity to the next seam is equal to zero, but this is only true when the expansion chamber is particularly wide and long. Generally, in a straight-through labyrinth, because the airflow passing through the slit can only spread to one side, the energy conversion from velocity energy (kinetic energy) to heat energy cannot be fully carried out in the expansion chamber, while the velocity of a part of the gas near the smooth wall does not decrease or only slightly decreases, and it directly crosses the top of each ten teeth and flows to the low-pressure side, which is called "ventilation effect".

Structure Type of Labyrinth

According to the different structures of seal teeth, the labyrinth can be divided into two types: seal piece and seal ring. The sealing piece has a compact structure, and it collides with the casing during operation. The sealing piece can bend to both sides, reducing friction and being convenient to disassemble and replace.

The sealing ring is composed of 6 to 8 sector blocks, which are installed in the casing and the rotating shaft. Each ring is pressed on the casing by a spring plate with a pressing force of about 60 to 100 N. When the important official collides with the toothed ring, the toothed ring bounces off by itself to avoid friction. This structure is large in size, complicated in processing, and the whole sealing ring is replaced after the teeth are worn, so it is not as widely used as the sealing ring structure.

Leakage Calculation of the Ideal Maze

Given the following conditions:

1. The leaked gas is an ideal gas, regardless of the Jiaol-Thomson effect, that is, the enthalpy of the gas is only related to the temperature.

2. Assuming that the maze is a series of continuous multiple slits, the expansion chamber between the two slits is large enough.

3. The flow through the steam is expanded in adiabatic circulation, and a flow coefficient A is quoted here.

4. The flow velocity energy after passing through the seam is completely recovered at constant temperature in the expansion chamber due to the control of equal pressure, so the velocity before each seam is asymptotically zero, that is, no air permeability occurs.

Characteristics of the Straight-through Maze

Because it is easier to machine grooves or teeth of various shapes on the shaft surface than in 7L, the holes are often machined into smooth ones, which form a labyrinth with the shafts with grooves or teeth. This is the straight-through labyrinth, which is the most widely used because of its convenient manufacture. However, there is ventilation in the straight labyrinth, and its leakage is larger than that of the ideal labyrinth.

Influencing Factors of Labyrinth Characteristics:

1. The influence of teeth. According to the tests conducted abroad, it is concluded that when the tooth pitch is constant, the more the number of teeth is, the less the leakage will be. When the pitch is in a coup, the larger the pitch is, the leakage will drop sharply, and the influence of air permeability can be reduced.

2. Influence of expansion chamber. The influence of expansion chamber depth abroad has been studied experimentally, and the conclusion is that a shallow expansion chamber is beneficial to reduce leakage.

According to the observation of the flow state in the expansion chamber, it is considered that the vortex in the shallow expansion chamber is unstable. Because the vortex can quickly exhaust the energy, the asymptotic velocity of the expansion chamber decreases, which has the effect of reducing leakage.

3. The influence of the auxiliary room. The so-called "auxiliary chamber" refers to the auxiliary groove of the straight-through labyrinth which is smooth and open upward. After the groove is opened, the flow state in the labyrinth changes obviously immediately. The test proves that as long as the position of the auxiliary chamber is appropriate, the reduction rate of leakage is quite large.

Clearance of the Labyrinth Gas Seal

Except in special cases, general turbomachinery such as gas turbines adopt labyrinth gas seals. The radial clearance should be selected according to the following factors: bearing clearance and manufacturing tolerance, error with packing, deformation of parts (such as casting shrinkage and out-of-round), deflection of the rotor, amplitude when passing through critical rotation frequency, thermal expansion and deformation caused by it, etc. In many cases, the influence of thermal expansion is prominent. Therefore, it is necessary to estimate the change in the size of a single component and the relative displacement of the components in advance when starting and stopping. Static and dynamic finite element methods can be used to calculate the time-varying thermal expansion law so that we can know which critical conditions are and how big the gap should actually be.

Points for Attention in Labyrinth Seal Design

Summing up the experience accumulated in labyrinth seal design as follows:

1. Try to convert the kinetic energy of the airflow into heat energy, without the residual velocity entering the next gap. Keep a proper distance from the teeth, or use high-low teeth to change the direction of airflow. The tooth spacing is generally between 5 and 9mm.

2. The sealing teeth should be as thin as possible with acute angles. The thickness of the tooth tip should be less than 0.5mm. When the tooth tip occasionally collides with the shaft during operation, the tooth tip will wear out first and get out of contact, so as not to cause an accident due to local overheating of the shaft due to friction.

3. Due to the large leakage of labyrinth seal, attention should be paid to preventing environmental pollution when sealing flammable, explosive or toxic gases. The inflatable labyrinth seal is adopted, and inert gas is introduced into the gap, the pressure of which is slightly higher than that of the sealed gas. If the medium is not allowed to be mixed with aeration, the air extraction labyrinth seal can be adopted.