1. Threaded Connection

Threaded connection usually process the end of inlet & outlet valves into taper pipe threads, which can make it screwed into the screwed joint of taper pipe or taper pipe line. We use sealant, sealing tape or the filler to block the big leakage channel for which may appear after this kind of connection. If the material of the valve can be soldered, we can choose to take seal weld after the threaded connection. However, even if the connection material can be soldered, when the coefficient of expansion differs greatly, or the variation range of the working temperature is big, the parts of the Threaded connection must take seal weld.

Threaded connection mainly use in the valves whose DN is under 50 mm. If the DN of a valve is too big, the installation and the seal of the threaded connection can be difficult.

To make it easier to install and take down the valve with threaded connection, we can use pipe joint in the proper position of the pipeline system. And we can use fitting union as pipe joint to connect two parts of the vales whose DN is under 50 mm, by using screw threads form the fitting union.

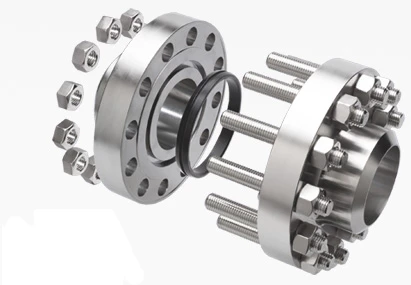

2. Flange Connection

It’s more convenient to install and take down the valve with flange connection. As flange connection has the heavier weight than threaded connection, the price of flange connection is higher than threaded connection, too. And, it fits various valves and different pressures’ pipe connection. However, when the temperature is over 350℃, the bolt, shim and the flange can be loose, and it will obviously decrease the load of the bolt, which can make the high-stressed flange connection to let out.

3. Welded Connection

Welded connection applies to all kinds of pressure and temperature. When it used in some extreme conditions, it will be more reliable than flange connection. As the tear-down and re-installation of the valve with welded connection can be more difficult, the welded connection can only use in occasions that need long-term and reliable operation or extreme conditions with high temperature, such as, heat power station, nuclear engineering and PVC engineering.

The valves with welded connections whose DN is under 50 mm usually have welded socket to take over valves of the plane. At the same time, the socket welding will form a crack between socket and pipe which may let the crack be corroded by some medium, and the vibration of pipes will make the connection part become fatigue, so that the usage of welded connection will be limited.

We usually use groove welded connection when we meet the occasion with big DN, extreme condition and high temperature, and we also have strict requirements to the welding line.