A Brief Introduction to Fully Welded Fixed Ball Valves for Gas:

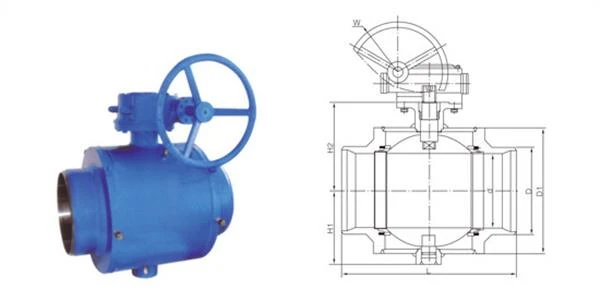

Fully Welded ball valve is widely used in underground pipelines of city gas, natural gas transmission pipelines, pressure regulating stations and other fields. In the past several years, through continuous research and innovation, as well as continuous improvement of product quality, fully Welded ball valves win more favour of customers.

Details of fully welded fixed ball valves for gas:

Fully welded ball valve, as the whole structure of the valve adopts a fully welded process structure, the inner and outer seals of the valve are greatly improved, the valve volumn is greatly reduced (especially below DN300), and the installation of the valve becomes more convenient, which not only reduces the cost of engineering construction, but also saves time.

Directly buried type fully-welded ball valve can be directly buried underground. There is no need to set up an underground valve control room, so that the operation does not need to enter the ground, only using the T-shaped handle for transmission operation on the ground, which is very convenient and avoids unsafe hidden dangers existing in the past due to the arrangement of the underground valve control room.

Directly buried fully welded ball valve can be designed for different valve heights according to the buried depth of user's gas pipeline. At the same time, according to the different needs of users for valve connection ports, there are various designed port connection modes to choose from.

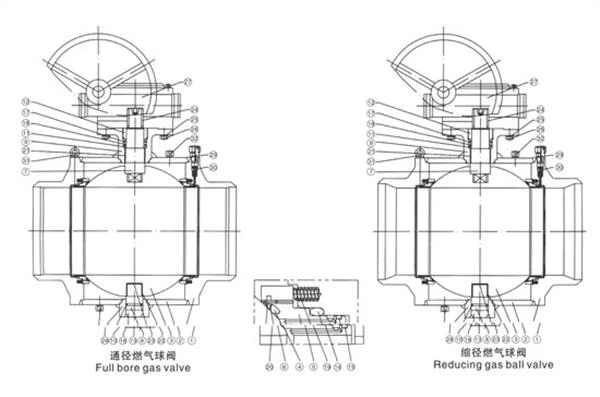

Material Chart of Fully Welded Fixed Ball Valve for Gas:

Fully welded fixed ball valve for gas:

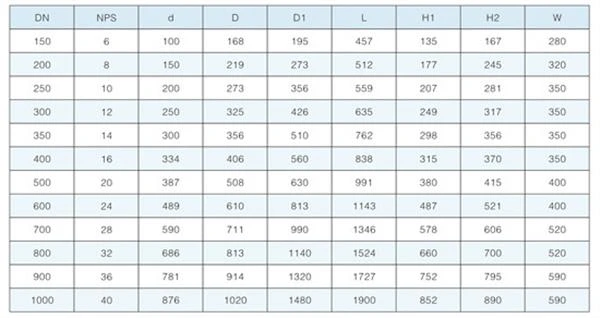

Main dimensions: PN16/PN25/PN40/CLASS 300.

(Reduced diameter, unit: mm)

(Reduced diameter, unit: mm)