Plug-valve:

Plug valves adopt cock bodies with through holes as their valve discs. The valve is opened and closed by the cock body rotating along with the valve stem. The small packless plug valve is also named as Cock.

Plug valves, refer to straightway valves able to be opened and closed rapidly, which usually work for media with suspended particles since the friction between valve plugs and sealing surfaces can completely avoid the contact with flow media when the valves are fully opened. The valve has another important property making it suitable for multi-channel structures, which means one plug valve is able to be connected to two to five flow channels. This property simplifies the design of pipeline systems, decreases the required amount of the valve in pipeline systems and reduces the need of facilities' connection fittings.

The plug valve has a conical (or cylindrical) plug. The plug and the conical surface form the sealed auxiliary of the plug valve. As one of the most ancient valve, a plug valve has the simple structure, quick opening-and-closing ability and small fluid resistance. A normal plug valve is sealed by finished metal plug body direct contact with the valve body. This kind of seal can cause poor sealing performances, big force when the valve is opened and closed and bad wear resistance of the plug valve, which makes the common plug valve only operated under conditions with the low pressure (not higher than 1Mpa) and the small diameter (less than 100mm).

About the operating and maintenance of the plug valve, it is necessary to pay attention to leave some space for the valve stem to rotate and not to use the plug valve to regulate any flows.

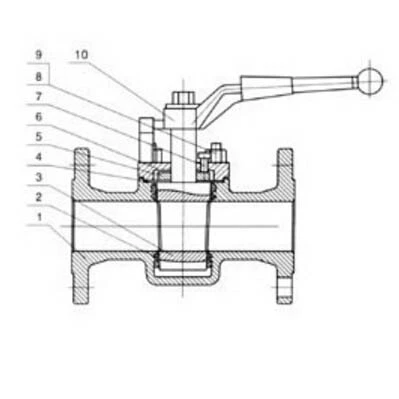

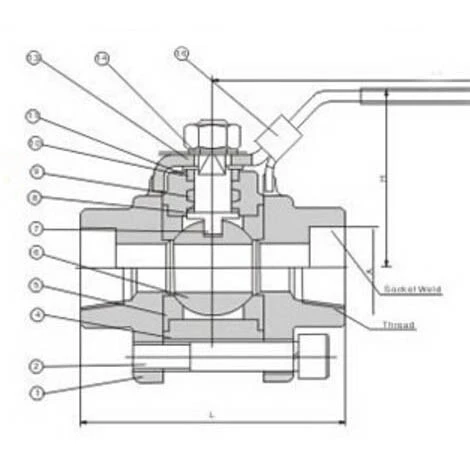

Ball valve:

Ball valves, as the improvement of plug vales, belong to the same valve type as plug valve. What the ball valve typically differs from the plug valve is that the ball valve adopts the ball as its disc instead of the plug. The ball of the ball valve opens and closes the valve by rotating around a quarter turn. The ball valve is mainly used to regulate, distribute and change the flow direction of the media and can even regulate flow with a V-shaped opening. In a word, the ball valve gets all the advantages of the plug valve' s while it gets rid of plug valve' s disadvantages, showing a great sealing performance.

The ball valve has the circular passageway. The full bore circular passageway straightly connects the circular passageway of the valve body, so the flow resistance is quite small.

The multi-channel ball valve, as one of fast-developing valves, can realize the distribution and flow direction of the media.

Plug valves adopt cock bodies with through holes as their valve discs. The valve is opened and closed by the cock body rotating along with the valve stem. The small packless plug valve is also named as Cock.

Plug valves, refer to straightway valves able to be opened and closed rapidly, which usually work for media with suspended particles since the friction between valve plugs and sealing surfaces can completely avoid the contact with flow media when the valves are fully opened. The valve has another important property making it suitable for multi-channel structures, which means one plug valve is able to be connected to two to five flow channels. This property simplifies the design of pipeline systems, decreases the required amount of the valve in pipeline systems and reduces the need of facilities' connection fittings.

The plug valve has a conical (or cylindrical) plug. The plug and the conical surface form the sealed auxiliary of the plug valve. As one of the most ancient valve, a plug valve has the simple structure, quick opening-and-closing ability and small fluid resistance. A normal plug valve is sealed by finished metal plug body direct contact with the valve body. This kind of seal can cause poor sealing performances, big force when the valve is opened and closed and bad wear resistance of the plug valve, which makes the common plug valve only operated under conditions with the low pressure (not higher than 1Mpa) and the small diameter (less than 100mm).

About the operating and maintenance of the plug valve, it is necessary to pay attention to leave some space for the valve stem to rotate and not to use the plug valve to regulate any flows.

Ball valve:

Ball valves, as the improvement of plug vales, belong to the same valve type as plug valve. What the ball valve typically differs from the plug valve is that the ball valve adopts the ball as its disc instead of the plug. The ball of the ball valve opens and closes the valve by rotating around a quarter turn. The ball valve is mainly used to regulate, distribute and change the flow direction of the media and can even regulate flow with a V-shaped opening. In a word, the ball valve gets all the advantages of the plug valve' s while it gets rid of plug valve' s disadvantages, showing a great sealing performance.

The ball valve has the circular passageway. The full bore circular passageway straightly connects the circular passageway of the valve body, so the flow resistance is quite small.

The multi-channel ball valve, as one of fast-developing valves, can realize the distribution and flow direction of the media.

Differences in applications:

For the function of blocking media, plug valves can better control flow than ball valves. But the advantage of plug valve is limited. The sealing surface of the plug valve is much larger than the ball valve's, which brings a better sealing performance to the plug valve, but also makes the plug valve operated with inflexibility because of the high torque. In general, the plug valve is seldom produced with the big caliber due to the weight of the plug itself.

If a valve in a large size adopts the inverted plug structure, that is, the larger diameter end of the plug is put down, it will inevitably reduce the sealing performance under the action of gravity. Therefore, the valve can only be sealed by greasing and the valve with lubricating grease will only be used for the storage and transportation of natural gas and petroleum since the lubricating grease can pollute media flowing through the valve.

About the ball valve, in theory, it has a worse sealing performance than the plug valve. However, the ball valve can be made to have a large diameter. Ball valves' sealing performance can meet most requirements of practical applications due to the technological improvement of machining accuracy and the sealing material, which may makes them even obtain a wider scope of applications.

For the function of blocking media, plug valves can better control flow than ball valves. But the advantage of plug valve is limited. The sealing surface of the plug valve is much larger than the ball valve's, which brings a better sealing performance to the plug valve, but also makes the plug valve operated with inflexibility because of the high torque. In general, the plug valve is seldom produced with the big caliber due to the weight of the plug itself.

If a valve in a large size adopts the inverted plug structure, that is, the larger diameter end of the plug is put down, it will inevitably reduce the sealing performance under the action of gravity. Therefore, the valve can only be sealed by greasing and the valve with lubricating grease will only be used for the storage and transportation of natural gas and petroleum since the lubricating grease can pollute media flowing through the valve.

About the ball valve, in theory, it has a worse sealing performance than the plug valve. However, the ball valve can be made to have a large diameter. Ball valves' sealing performance can meet most requirements of practical applications due to the technological improvement of machining accuracy and the sealing material, which may makes them even obtain a wider scope of applications.

|

|

| Plug Valve | Ball Valve |