What is a butterfly check valve?

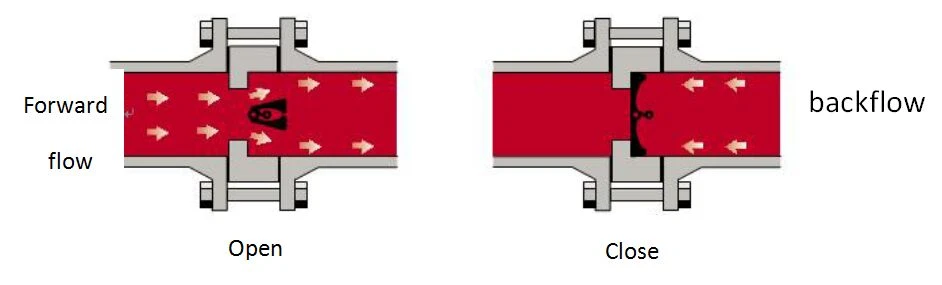

Butterfly check valve or double disc check valve overcomes the limitation of diameter and pressure drop of swing check valve and disc check valve. The disc of swing check valve is divided into two and hinged in the middle. In this way, the two discs can only swing in one direction. The discs are pressed against the valve seat by the torsion spring mounted on the hinge. In order to have a hinge in the center of the flow passage, a fixing pin needs to be installed outside, which will cause leakage of the valve. After the design is improved, it can be installed inside, and the fluid can be sealed inside the valve without leaking to the outside (see the following schematic diagram).

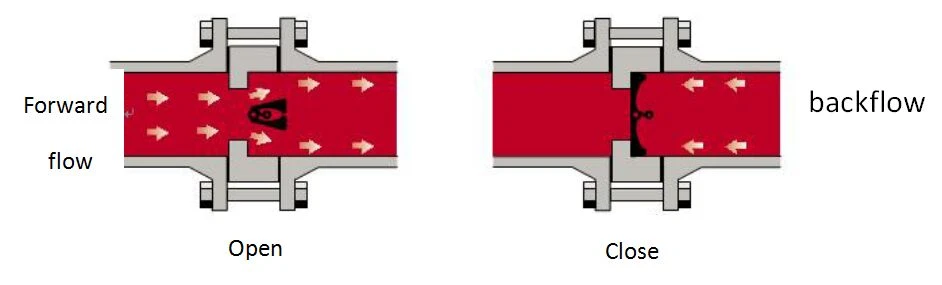

The butterfly check valve in the above figure is usually closed due to the force of the torsion spring. When the fluid flows forward, the pressure of the fluid makes the disc rotate around the hinge and the valve opens. Once the fluid stops, the valve is closed before flowing back due to the action of spring.

Working principle:

If the root of the disc wears the valve seat during normal operation, frequent opening and closing of the butterfly check valve will soon cause damage to the valve seat. To overcome this problem, when the valve is just opened, the root of the disc is lifted, and the disc only rotates around the hinge. Compared with other check valves, butterfly check valves have many advantages: butterfly check valves are not limited by caliber and can reliaze a dimension of DN5400; the pressure drop through the check valve is much lower than that through other check valves; can be used for occasions with low opening pressure; can be installed at any position.

Butterfly check valve or double disc check valve overcomes the limitation of diameter and pressure drop of swing check valve and disc check valve. The disc of swing check valve is divided into two and hinged in the middle. In this way, the two discs can only swing in one direction. The discs are pressed against the valve seat by the torsion spring mounted on the hinge. In order to have a hinge in the center of the flow passage, a fixing pin needs to be installed outside, which will cause leakage of the valve. After the design is improved, it can be installed inside, and the fluid can be sealed inside the valve without leaking to the outside (see the following schematic diagram).

Schematic Diagram of Butterfly Check Valve

The butterfly check valve in the above figure is usually closed due to the force of the torsion spring. When the fluid flows forward, the pressure of the fluid makes the disc rotate around the hinge and the valve opens. Once the fluid stops, the valve is closed before flowing back due to the action of spring.

Working Schematic Diagram of Butterfly Check Valve

Working principle:

If the root of the disc wears the valve seat during normal operation, frequent opening and closing of the butterfly check valve will soon cause damage to the valve seat. To overcome this problem, when the valve is just opened, the root of the disc is lifted, and the disc only rotates around the hinge. Compared with other check valves, butterfly check valves have many advantages: butterfly check valves are not limited by caliber and can reliaze a dimension of DN5400; the pressure drop through the check valve is much lower than that through other check valves; can be used for occasions with low opening pressure; can be installed at any position.