The axial flow check valve, also known as a non-slam check valve, silent check valve, or shuttle check valve, is commonly used in various pipeline systems. Its main job is to prevent backflow and protect equipment from damage caused by reverse liquid flow. As a type of one-way check valve, the axial flow check valve not only does what a regular check valve does, but it also offers some extra benefits. These include reducing water hammer, cutting down on noise, lowering pressure drop, and boosting response speed. Its unique design makes it a great choice for many industries, especially in pump discharge and other key pipeline systems.

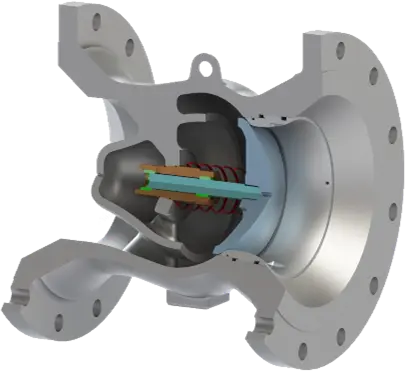

The axial flow check valve combines a streamlined design with an efficient sealing structure. This helps optimize fluid flow and reduce both flow resistance and water hammer. The valve body uses a cast-forged integrated design, which gives it added strength and safety. The valve disc and buffer spring work together to improve sealing performance and response time. This makes the valve open and close smoothly and efficiently, even at high speeds.

One of the main perks of the axial flow check valve is its Venturi streamlined flow path design. This design smooths out the flow path, cuts down on fluid resistance, and helps the fluid move more easily. It also boosts the valve's responsiveness and reduces the pressure drop that can occur with fluid flow.

The valve body is made with a solid cast-forged design, which helps prevent leaks and ensures the valve's strength and sealing ability. The valve disc is designed to reduce water hammer and noise. It uses a low-noise disc structure that opens smoothly as fluid flows through. This helps avoid the noise and vibration caused by the impact of the valve disc. Additionally, guide supports are placed at both ends of the disc. This allows the valve to be installed horizontally, vertically, or at any angle, making installation more flexible and adaptable.

The sealing design of the axial flow check valve is top-notch. It uses a valve seat structure that combines hard and soft seals. This ensures excellent sealing performance, even under low backpressure conditions. This design fixes the common problem in traditional check valves, where sealing can fail under low backpressure. The floating plate structure also automatically adjusts for any wear that happens during installation or use. This ensures the sealing surface stays tightly in place, improving sealing performance and extending the valve's lifespan.

The axial flow check valve works based on its unique axial flow switching structure and buffer spring design. When fluid flows, the valve disc opens smoothly, and the fluid passes through the valve's axial flow passage. The spring acts as a buffer during this process, preventing impact and vibration that are common in regular check valves. If the flow reverses, the valve disc quickly closes and seals tightly against the valve seat to prevent backflow. The combination of hard and soft seals helps reduce the noise that typically occurs when the disc and valve seat meet.

This design allows the axial flow check valve to quickly respond to pressure changes in the fluid, minimize water hammer, and keep the flow steady and safe.

The axial flow check valve has several standout advantages, such as:

Low Fluid Resistance: The streamlined design reduces fluid resistance, improving the system's energy efficiency.

Low Water Hammer Pressure: The valve disc shuts quickly, effectively preventing water hammer and reducing the impact on pipes and equipment.

Low Noise: The low-noise design reduces vibration and noise during the valve's opening and closing.

Great Sealing Performance: Even under low backpressure conditions, the valve maintains excellent sealing, ensuring system safety.

Quick Response: The valve responds quickly to changes in fluid pressure, keeping the system stable.

Thanks to its great performance, the axial flow check valve is used in many different fields. It plays a crucial role in preventing backflow, reducing water hammer, and cutting down on noise. It's especially useful in long-distance pipelines for oil and gas, compressors in large ethylene plants, and pump discharge points. It's an essential part of liquid flow protection systems, ensuring pipelines remain stable and equipment stays safe.

This valve is also widely used in water supply and drainage systems, fire protection systems, and HVAC (Heating, Ventilation, and Air Conditioning) systems. It's particularly helpful in pump discharge applications, where it prevents water hammer and protects pumps from reverse flow and damage.

When installing the axial flow check valve, make sure that the fluid flow direction matches the arrow on the valve body. This is crucial for the valve to work correctly. For larger check valves, it's recommended to provide proper support to avoid excessive pressure from the pipeline affecting the valve. This ensures smooth and stable operation.

The axial flow check valve is designed for durability and easy maintenance, making it ideal for long-term use. Regular checks of the valve's sealing and the movement of the valve disc will ensure it operates smoothly. Thanks to its floating plate structure and hard-soft seal design, the valve automatically compensates for any wear during installation or use, maintaining excellent sealing performance and a long service life.

With its unique design and top-notch performance, the axial flow check valve is a key player in pipeline systems. Its low flow resistance, low water hammer, low noise, and excellent sealing make it a perfect replacement for traditional check valves. Whether it's in pump discharge points, long-distance pipelines, or water supply, drainage, and fire protection systems, the axial flow check valve protects pipelines, prevents backflow, reduces water hammer, and cuts down on noise. This ensures the entire system stays safe and stable.