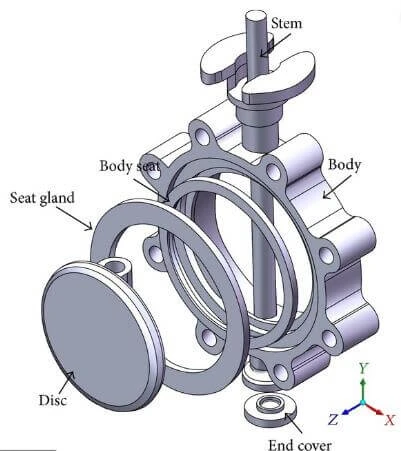

Because the wipIng motion of the butterfly valve plate, most butterfly valves can be used for medium with suspended solid particles, and can also be used for powder and granular medium according to the strength of seal.

The butterfly valve has small structural length and overall height, fast opening and closing speed, small fluid resistance when fully opened, and sensitive flow control when opened to about 15° to 70°. The structural principle of butterfly valve is most suitable for making large diameter valves.

Under the following working conditions, butterfly valves are recommended:

① Where throttling and regulating control flow are required.

② Where there are mud media and media containing solid particles.

③ Where a short valve structure length is required.

④ Where fast opening and closing speed is required.

⑤ Where the pressure difference is small.

In case of two-position adjustment, necking channel, low noise, cavitation and gasification, a small amount of leakage to the atmosphere and abrasive medium, butterfly valve can be selected.

When using butterfly valves under special working conditions, such as throttling adjustment or strict sealing requirements, or severe wear, low temperature (deep cooling), it is necessary to use a triple eccentric or double eccentric butterfly valves with particular design of metal seals with adjusting devices.

The signal butterfly valve is driven by the worm gear to drive the rotating shaft and butterfly plate to open and close and flow control. Rotate the handwheel of the worm gear transmission device to meet the goal. The handwheel rotates clockwise to close the valve.

Device Using:

Connect the core wire of the cable to the corresponding terminal according to the electrical control requirements, seal the cable inlet and fix the cable at the same time, so as to prevent the cable connection from being damaged by external force.

When the valve is in the "fully closed" position, turn the lower closing cam clockwise or the upper opening cam counterclockwise. When the butterfly valve clamps the pipeline, pay attention to whether the connecting force is uniform and reliable.

After the butterfly valve is installed, the valve plate must be in the open position during the pipeline strength test. After the installation, it should be inspected regularly. The main items of inspection are as follows: whether the butterfly valve seat and O-ring seal are damaged.

Check the sealing performance of valve plate sealing surface. After the butterfly valve is overhauled and assembled, there shall be no jam when opening and closing. After the butterfly valve is repaired and assembled, the sealing performance test shall be carried out as required.

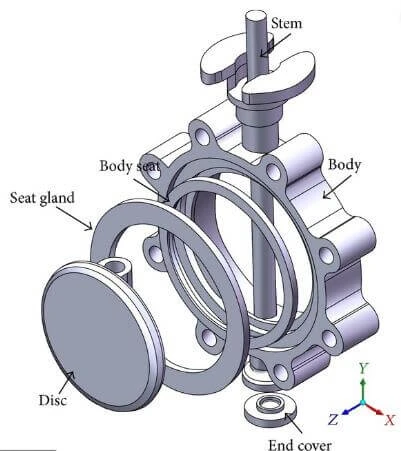

The butterfly valve has small structural length and overall height, fast opening and closing speed, small fluid resistance when fully opened, and sensitive flow control when opened to about 15° to 70°. The structural principle of butterfly valve is most suitable for making large diameter valves.

Under the following working conditions, butterfly valves are recommended:

① Where throttling and regulating control flow are required.

② Where there are mud media and media containing solid particles.

③ Where a short valve structure length is required.

④ Where fast opening and closing speed is required.

⑤ Where the pressure difference is small.

In case of two-position adjustment, necking channel, low noise, cavitation and gasification, a small amount of leakage to the atmosphere and abrasive medium, butterfly valve can be selected.

When using butterfly valves under special working conditions, such as throttling adjustment or strict sealing requirements, or severe wear, low temperature (deep cooling), it is necessary to use a triple eccentric or double eccentric butterfly valves with particular design of metal seals with adjusting devices.

The signal butterfly valve is driven by the worm gear to drive the rotating shaft and butterfly plate to open and close and flow control. Rotate the handwheel of the worm gear transmission device to meet the goal. The handwheel rotates clockwise to close the valve.

Device Using:

Connect the core wire of the cable to the corresponding terminal according to the electrical control requirements, seal the cable inlet and fix the cable at the same time, so as to prevent the cable connection from being damaged by external force.

When the valve is in the "fully closed" position, turn the lower closing cam clockwise or the upper opening cam counterclockwise. When the butterfly valve clamps the pipeline, pay attention to whether the connecting force is uniform and reliable.

After the butterfly valve is installed, the valve plate must be in the open position during the pipeline strength test. After the installation, it should be inspected regularly. The main items of inspection are as follows: whether the butterfly valve seat and O-ring seal are damaged.

Check the sealing performance of valve plate sealing surface. After the butterfly valve is overhauled and assembled, there shall be no jam when opening and closing. After the butterfly valve is repaired and assembled, the sealing performance test shall be carried out as required.