Product Item: Double Face Submerged Arc Welding Spiral Steel Pipes

OD DIMENSION: Φ219-Φ3500mm

Wall Thickness: 6-25.4mm

Coating: FBE / 2 FBE Fusion Bonded Epoxy Powder

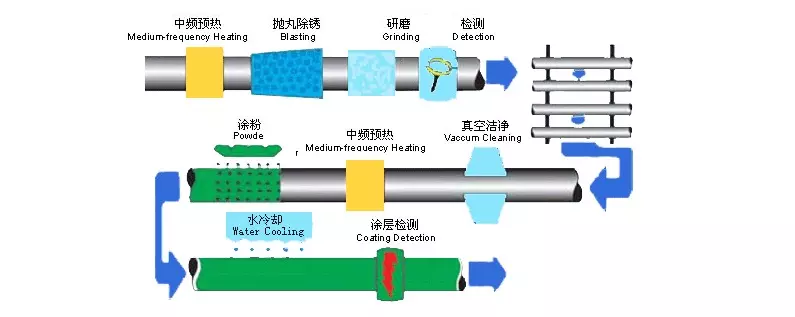

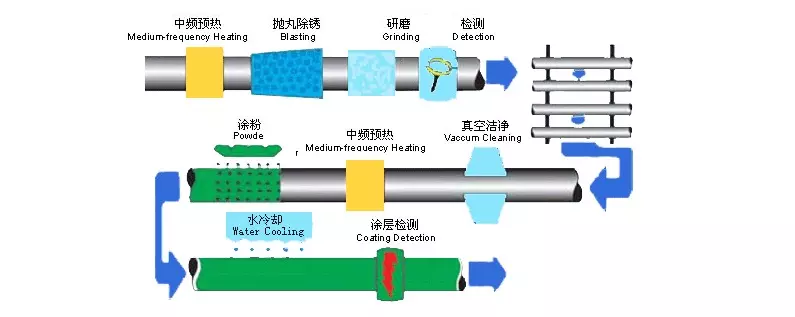

There are two kinds: single-layer and double-layer. Single-layer FBE coating adopts special fusion bonded epoxy powder coating as film-forming material, taking the electrostatic spraying coating epoxy powder coating process, forming the coating layer at one time. This epoxy powder is one kind of thermosetting coating. It is made of solid epoxy resin, a curing agent, and various additives. We need to sandblast and medium frequency preheat the pipe, before spray painting, then use the electrostatic spraying method in the application of epoxy powder coating the steel tube of the heating surface, molten adhesive on the steel pipe surface, and solidified to form the coating. Generally speaking, FBE coating forms the coating layer at one time. FBE coating has many advantages, such as strong adhesive to the steel, good completeness of the film, resistance to cathodic dis-bonding, resistance to soil stress, and stand wear and tear, the coating operation is simple, and pollution-free. The coating has a good ability to counter bending and impact and high-temperature resistance, which makes it widely used in a lot of countries. FBE coating can be used as the outside coating of steel-buried pipelines or submarine pipelines in the -30°C - +100°C environment.