With the implementation of the national belt and road initiative policy, the business of domestic electric power design institutes has gradually expanded to the European continent. European standards are widely adopted in Europe, which is different from American standards (mainly used in Southeast Asia, the Middle East and South America) or national standards that are routinely used by domestic design institutes. At present, the owners of the projects to be implemented tend to use European standards. This is a brand-new topic for the Electric Power Design Institute. After all, there are not many European standard projects in the past, and the European standard is not familiar in China. Pipeline engineering involves the European standard for the design, manufacture and inspection of pipelines and pipe fittings. In this paper, limited by space, pipe fittings are selected for standard comparison. Butt-welding pipe fittings (EN 10253) (Butt-welding pipe fittings) are widely used in the domestic power industry. EN 10253 is divided into four parts, which are part 1: forged carbon steel for general use and without special inspection requirements; Part 2: Non-alloy and ferritic alloy steel with special inspection requirements; Part 3: forged austenitic and austenitic-ferritic (duplex) stainless steel without special inspection requirements; Part 4: Forged austenitic and ferritic-austenitic (duplex) stainless steels with special inspection requirements. Part 2 is widely used in the electric power industry. Therefore, this standard comparison study is mainly the comparison between Butt-welding pipe fittings—Part 2: nonalloy and ferrous alloy steels with specific inspection requirements (EN 10253-2-2007) and Butt-welding pipe fittings (DL/T 695—2014).

1. Comparison of standard application scope of pipe fittings between China and Europe

DL/T 695 specifies the basic requirements of carbon steel, alloy steel and austenitic stainless steel for welded pipe fittings. This standard is applicable to steel butt welded pipe fittings used in thermal power plants and non-nuclear grade steel butt welded pipe fittings in nuclear power plants. Part 2 of EN 10253-2 specifies the technical requirements for seamless and butt welded pipe fittings (elbows, concentric and eccentric reducing pipes, equal-diameter tees and reducing tees, heads) made of carbon steel and alloy steel. These materials are designed for the transmission and distribution of fluids and gases at room temperature, low temperature or high temperature. Part 4 of EN 10253-2 specifies the basic requirements of stainless steel for welded pipe fittings. Through comparison, the application scope of the two pipes is the same, except that the national standard is more suitable for butt welded steel pipes used in thermal power plants and non-nuclear grade butt welded steel pipes used in nuclear power plants, while EN 10253-2 does not specifically refer to the power industry. Therefore, in the power industry, if European owners require the use of European standard pipes, European standard pipe fittings standards can be used.

2. Comparison of standard steel and pipe diameter between China and Europe pipe fittings

2. 1 Comparison of Standard Steel for Pipe Fittings between China and Europe

DL/T 695—2014 specifies various domestic commonly used steel types such as GB 3087, GB 5310, ASTM and EN 10216-2; Part 2 of EN10253 specifies that the carbon steel products are: p235tr2-p265tr2-p235gh-p265gh-p355n-p355nh-p355nl1-p215nl-p265nl. See EN 10027-1 for other steel products. The national standard does not mention the European standard carbon steel materials, while the European standard covers carbon steel, alloy steel, stainless steel and other materials. The European standard is more comprehensive in the application range of European standard pipes.

2. 2 Comparison of standard pipe diameters between China and Europe

1) Nominal size comparison

DL/T 695 in DN series, gives two kinds of outer diameter size series, namely A series and B series. Series A is an international general series, namely the ISO series. The nominal diameter DN of Part 2 of EN 10253-2 comes from ENISO 6708; Series outer diameter from EN 10220, and seamless steel pipe

Seamless steel tubes for pressure purposes-technical delivery conditions part 2: non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10216-2 and welded steel pipes: welded steel pipes for pressure purposes-technical delivery conditions part 2: Electric welded non-alloy and alloy steel pipes with SPE Outside diameter series of certified elevated temperature properties en10217-2 are consistent. The nominal size and outer diameter series of European standards are completely consistent with the A series of national standards.

2) Comparison of the size range

DL/T 695 specifies the butt welded pipe fittings of the outer diameter control pipe size series DN15~DN1 200 and the butt welded pipe fittings of the inner diameter control pipe size series 146~1 067. The dimension series specified in Part 2 of EN 10253-2 is DN15-DN1200. The domestic standard DL/T 695 specifies the size of the outer diameter control pipe and inner diameter control pipe respectively. European standards do not distinguish between the size of outer diameter control pipe and the size range of inner diameter control pipe, and the diameter range is consistent with that of domestic control outer diameter pipe. The difference in size specification is due to the difference in actual processing capacity in different countries. When adopting different standards, attention should be paid to the regulation of their size range, and products that cannot be purchased should be avoided.

3. Comparison of types and pressure grades of standard pipe fittings between China and Europe

3. 1 Comparison of Standard Pipe Fittings between China and Europe

The domestic standard DL/T 695 does not distinguish between Class A and Class B according to whether the wall thickness of pipe fittings is the same as or increases with the wall thickness of connected straight sections. EN 10253-2 defines two types of pipe fittings: the wall thickness of the welded end of type A pipe fitting and the pipe fitting body is the same as that of the connecting straight pipe. Generally, their bearing capacity to internal pressure is smaller than that of straight pipes of the same size. The wall thickness of B-shaped pipe fittings is increased at the main body of the pipe fittings, so as to bear the same internal pressure as straight pipes of the same size. These two types of pipe fittings are used in the applications covered by EU Directive 2014/68/EU. Type a: butt welded pipe with reduced pressure coefficient x; The pressure coefficient x is defined as the pressure on the pipe fitting/the pressure on the straight pipe. For example, the pressure coefficient x of the welded elbow with a 2D bending radius of OD711×7.1 (wall thickness corrosion allowance 1 mm) is only 67%. Type b: butt welded pipe fittings used under full working pressure. According to this definition, the pressure piping system in the power industry generally adopts Class B pipe fittings. 3. 2 The pressure grade and strength are not specified in DL/T 695—2014 compared with the standard pressure grade of pipe fittings between China and Europe. In Part 2 of EN 10253-2, the wall thickness of Class B pipe fittings has set up 8 pressure grade series (the pressure values are not specifically defined in these 8 pressure grade series). Each series corresponds to the selected wall thickness of a straight pipe, and each pipe fitting has specific wall thickness parameters corresponding to the selected wall thickness of the straight pipe. For elbows, according to different bending radii, the minimum inner arc wall thickness Tint is defined. It can be seen that the strength (wall thickness) of pipe fittings of specific materials corresponding to specific pressure grades is not specified in the national standard and European standards. European standard only lists the wall thickness of pipe fittings under the recommended 8 pressure grade series but does not specifically define the pressure value. In addition, although the domestic standard DL/T 695—2014 does not specify the pressure grade and strength, in order to facilitate the selection, processing, manufacturing and procurement of steam-water pipes and fittings in thermal power plants, China Electric Power Design and Planning Association compiled Typical Design of Steam-water Pipe Parts and Components in Thermal Power Plants (GD 2016). "2016 Standard Pipe" is applicable to the design of metal steam-water pipe parts and components for units with ultra-supercritical parameters and below in thermal power plants, the design temperature of the pipe is not more than 628℃, and the capacity is not more than 1 000 MW. The manual of the 2016 Standard Pipe covers steel pipe varieties, elbows, reducers, tees, heads, flanges and assemblies, etc. This standard pipe has a feature, which sets the identification code of pipes or pipe fittings. The code has at least six units: the first unit is the name code; The second unit is the grade code, which is expressed by design pressure or design temperature. The third unit is material type; The fourth unit is the material code; The fifth unit is the type code; Unit 6 is the specification code. After identification and coding, the listing of pipes and pipe fittings is convenient for understanding the characteristics and materials of pipes and pipe fittings, and convenient for retrieval and standardized design. It is understood that due to intellectual property issues, there is no corresponding regulatory manual prepared by domestic trade associations in European standards. It is suggested that when the European standard is used, manufacturers capable of designing and manufacturing European standard pipe fittings should calculate the strength (strength design) according to the specific pressure grade, material and pipe fitting type of the pipe fittings according to the dimensions specified in these standards, so as to determine the specific wall thickness of the pipe fittings.

4. Comparison of Standard Dimensions, Wall Thickness and Form and Position Tolerance between Chinese and European Pipe Fittings

4. 1 Comparison of Standard Dimensional Tolerance between Chinese and European Pipe Fittings

DL/T 695—2014 lists the dimensional tolerances of various pipe fittings of outer diameter control pipe in Schedule E.1, which are specific values. The positive deviation of dimension is from 1.0 mm in DN 15 to 6.4mm in DN 1 200; The negative deviation is from 0.8 mm in DN 15 to 4.8 mm in DN1 200. Part 2 of EN 10253-2 defines that the dimensional deviation of pipe fittings is 1% or 0.5mm, whichever is greater, but the maximum is 5mm. In fact, the size deviation of European pipe fittings is slightly stricter than that of the national standard, which puts forward higher requirements for domestic pipe fittings manufacturers to produce European pipe fittings.

4. 2 Comparison of Wall Thickness Tolerance of Standard Welded End of Chinese and European Pipe Fittings

According to DL/T 695—2014, the maximum deviation of the wall thickness of the welding end is from 0.9 mm (DN≤65) to 5.6 mm (1 050≤DN≤1 200). Part 2 of EN 10253-2-2007 specifies the deviation of the wall thickness of welded end (for B-type pipe fittings): when the outer diameter is ≤610 mm, the deviation is-12.5%, +20% regardless of the wall thickness. When the outer diameter is > 610 mm, it can be divided into three categories:

1) Seamless pipe fittings, wall thickness-12.5%, +20%.

2) Weld pipe fittings with wall thickness ≤10 mm and deviation -0.35 mm, +20%.

3) Weld pipe fittings with wall thickness > 10mm, deviation -0.5 mm, +20%.

It can be seen from the above that for welded pipe fittings, the absolute value of the negative deviation of wall thickness required by the European standard is small, and there is no specific requirement in this aspect in the national standard. In addition, for seamless pipe fittings and welded pipe fittings, the positive deviation of wall thickness in European standards is 20%, and there is no specific requirement in the national standard. It can be seen that, in general, the European standard has a narrower control range for wall thickness tolerance.

4. 3 Comparison of Standard Form and Position Tolerances between Chinese and European Pipe Fittings

According to DL/T 695—2014, when the nominal size is 15 - 100, the form and position tolerance x = 1 mm; X = 2 mm at 25 - 200; X = 3 mm at 25 - 400; X = 4 mm at 40 - 600; X=5 mm at 60 - 1 200. Part 2 of EN 10253-2 stipulates that the geometric tolerance X is ≤ 1% or 1 mm of the outside diameter of the measuring point, whichever is greater. When the European standard is used for large diameter pipe fittings, that is, DN>500, the form and position deviation is lower than that required by a national standard. When the diameter of DN<500, the deviation of form and position is consistent with the national standard, which is 1% of the outer diameter. The overall European standard is stricter than the national standard in form and position deviation. By comparing the size, wall thickness, shape and position deviation of Chinese and European standard pipe fittings, the allowable deviation range of European standard is narrower than that of national standard, and the overall requirements are stricter than that of national standard. The main reason is that the European manufacturing process is more sophisticated than that in China. If domestic pipe fittings factories need to manufacture European standard pipe fittings, they need to improve their manufacturing level.

5. Comparison of end groove forms of standard pipe fittings between China and Europe

DL/T 695 stipulates that when the nominal wall thickness of carbon steel and ferritic alloy steel is 5 mm≤tn≤22 mm and the nominal wall thickness of austenitic stainless steel is 3mm≤tn≤22 mm, a V-shaped groove shall be adopted; Nominal wall thickness ≥22mm, with double V-shaped groove; The rest is not specified. The bevel angle of the end of the V-groove is 37.5 2.5. The bottom surface is 1.5mm 1.0mm.. Part 2 of EN 10253-2 stipulates: According to the manufacturer's choice, for the specified wall thickness of less than 3 mm, both ends can be cut into squares or slightly chamfered. If the wall thickness is between 3 and 3-22 mm, the oblique angle of its end should be 30 5, and its bottom should be 1.6 mm±0.8 mm If the wall thickness exceeds 22 mm, it should be approved by the purchaser. By comparison, the Sino-European pipe fitting standards are almost identical in the end groove form and wall thickness grading of pipe fittings. The only difference is that the angle of bevel angle and the size of the bottom surface are slightly different, which depends on the processing and manufacturing characteristics of different countries, regardless of the advantages and disadvantages.

6. Comparison of Minimum Wall Thickness for Standard Calculation of Pipe Fittings between China and Europe

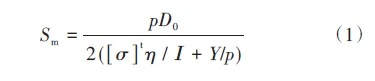

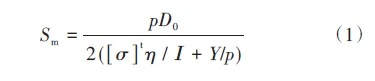

Comparative example: seamless elbow nozzle OD168.3×4.5, material P265GH, design pressure: 1.03 MPa (g), design temperature: 379℃, allowable stress of material: 91.29 MPa. For the sake of comparison, the bending radius is 1.5 times the outer diameter, regardless of wall thickness deviation and wear prediction. The strength design of domestic standard DL/T 695 pipe fittings comes from the steam code DL/T 5054—2016, and the formula for calculating the minimum wall thickness of the elbow is as follows:

Type:

P —— design pressure [MPa (g)];

D0 —— the outer diameter of the pipe;

[σ] t —— the allowable stress at the design temperature (MPa);

η-correction coefficient of allowable stress;

I-correction coefficient of elbow wall thickness;

Y-correction coefficient.

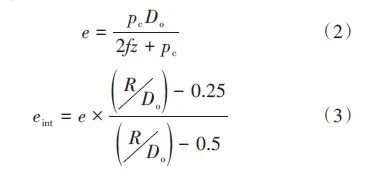

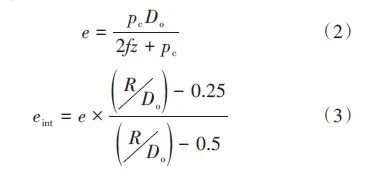

Sm=1.03×168.3/2× (91.29+0.4×1.03)=0.95 mm; The strength design of pipe fittings in part 2 of European standard EN 10253 comes from European standard EN 13480-3, and the minimum wall thickness formula of elbow inner arc is as follows:

When Do/Di≤1.7;

Type:

E —— minimum wall thickness of straight pipe (mm);

Pc-design pressure [MPa (g)];

Do —— the outer diameter of the pipe;

F —— allowable stress at design temperature (MPa);

Z —— weld coefficient;

R —— bending radius of the elbow (mm).

eint=1.03×168.3(/ 2×91.29×1+1.03) × (1.5-0.25)/(1.5-0.5)=1.18 mm; After comparison, the wall thickness deviation and wear allowance are not considered in the strength calculation standards of pipe fittings in China and Europe, and the European standard formula of the minimum wall thickness of elbow will be conservative.

7. Other Comparison of China-Europe Pipe Fitting Standards

7. 1 Comparison of Flow Area of Pipe Fittings between China and Europe

According to DL/T 695, the minimum inner diameter of the elbow and tee should ensure that the flow area is equal to that of the nozzle, and the flow area should not be less than 95% of that of the nozzle. Part 2 of EN 10253-2 stipulates that in order to ensure the normal flow of fluid through the pipe fittings, the inner diameter of any part of the pipe fittings (not applicable to the head) should be greater than 80% of the inner diameter ID. The national standard has higher requirements on the flow area than the European standard and is better in controlling the flow resistance of the medium.

7. 2 Comparison of Bend Radius between China and Europe

According to DL/T 695, it can be divided into a long radius (equivalent to 1.5 times the outer diameter) and a short radius elbow (equivalent to 1 times the outer diameter). Part 2 of EN 10253 stipulates that it can be divided into 2D (equivalent to 1.5 times the outer diameter), 3D (equivalent to 1.5 times the outer diameter) and 5D series (equivalent to 2.5 times the outer diameter). The expression of the series of bending radii in European standards is different from that in China, which is twice the bending radius in China. At the same time, the series of the bending radii are more abundant.

7. 3 Comparison of internal pressure instructions between Chinese and European pipe fittings

There is no administrative instruction for pressure equipment in domestic standards. Part 2 of EN 10253-2 makes it clear that the pressure equipment directive (2014/68/EU) stipulates that the design of sufficient strength should be based on the calculation method or limited to the experimental method. The resistance of pipe fittings conforming to this European standard to internal pressure should be based on EN 13480-3. It is the ultimate responsibility of the pressure equipment manufacturer to select the appropriate pipe fittings (material and thickness). Only products entering the European market need to comply with the EU directive, and pressure equipment just needs to comply with the PED directive (2014/68/EU). In addition, the last annex of Part 2 of EN 10253-2 also has an explanatory table on the compliance of this standard with the provisions of the European Union directive PED (2014/68/EU). This is a significant difference between European standards and domestic standards.

Conclusion

China's belt and road initiative policy urges domestic electric power design businesses to go abroad, to a wider overseas market, and to compete with large foreign engineering consulting companies for international projects. In the past, most overseas projects were in Southeast Asian countries or Middle Eastern countries. Now, our business has expanded to Europe. In addition to practicing the basic skills of national standards or American standards, we also need to be familiar with the local European design standards and habits. Similarly, domestic pipeline and pipe fittings manufacturers also need to study the European market norms simultaneously and jointly go out to sea to win the vast continental European market. This paper introduces the domestic pipe fitting standards and the European pipe fitting standards compared with them and compares the Chinese and European pipe fitting standards from many angles. The following conclusions are obtained:

1) European standards are used in a wider range of industries.

2) European standard is more comprehensive in the application range of pipes. The nominal size and outer diameter series of European standards are completely consistent with the A series of national standards. The range of European standard pipe diameter is consistent with the size of domestic controlled outer diameter pipe.

3) European standard EN 10253-2 distinguishes Class A and Class B according to whether the wall thickness of pipe fittings is the same as or increases with that of connected straight sections. The power pressure pipeline system in the industry adopts Class B pipe fittings, but there is no Class A classification. There is no regulatory manual prepared by domestic trade associations in European standards. It is suggested that when European standard is used, manufacturers capable of designing and manufacturing European standard pipe fittings should design according to the specific pressure grade, material and pipe fitting type of pipe fittings and draw the manufacturing drawings of European standard pipe fittings.

4) By comparing the size, welding end wall thickness and form deviation of standard pipe fittings between China and Europe, the European standard is stricter than the national standard. The main reason is that the European manufacturing process is more sophisticated than that in China. If domestic pipe fittings factories need to manufacture European standard pipe fittings, they need to improve their manufacturing level.

5) By comparison, the bevel angle and bottom dimension of the end groove of pipe fittings between China and Europe are slightly different, which depends on the manufacturing characteristics of different countries and regions.

6) Through the comparison of calculation examples, the European pipe strength calculation standard will be conservative and safer.

7) European pipe fittings have their own special places in terms of flow area and bend radius. In addition, all pipe fittings entering the European market need to comply with the PED Directive (2014/68/EU). Part 2 of EN10253-2 has a cross-reference on the compliance of this standard with the EU directive PED (2014/68/EU). This is a special point for domestic pipe fittings factories to enter the European market. Besides meeting the relevant European design, manufacturing and inspection standards, it also needs to comply with PED administrative instructions. The above conclusion points out the similarities and differences between Chinese and European pipe fitting standards, which have certain reference significance for domestic electric power design institutes and domestic pipe fitting manufacturers to understand.

1. Comparison of standard application scope of pipe fittings between China and Europe

DL/T 695 specifies the basic requirements of carbon steel, alloy steel and austenitic stainless steel for welded pipe fittings. This standard is applicable to steel butt welded pipe fittings used in thermal power plants and non-nuclear grade steel butt welded pipe fittings in nuclear power plants. Part 2 of EN 10253-2 specifies the technical requirements for seamless and butt welded pipe fittings (elbows, concentric and eccentric reducing pipes, equal-diameter tees and reducing tees, heads) made of carbon steel and alloy steel. These materials are designed for the transmission and distribution of fluids and gases at room temperature, low temperature or high temperature. Part 4 of EN 10253-2 specifies the basic requirements of stainless steel for welded pipe fittings. Through comparison, the application scope of the two pipes is the same, except that the national standard is more suitable for butt welded steel pipes used in thermal power plants and non-nuclear grade butt welded steel pipes used in nuclear power plants, while EN 10253-2 does not specifically refer to the power industry. Therefore, in the power industry, if European owners require the use of European standard pipes, European standard pipe fittings standards can be used.

2. Comparison of standard steel and pipe diameter between China and Europe pipe fittings

2. 1 Comparison of Standard Steel for Pipe Fittings between China and Europe

DL/T 695—2014 specifies various domestic commonly used steel types such as GB 3087, GB 5310, ASTM and EN 10216-2; Part 2 of EN10253 specifies that the carbon steel products are: p235tr2-p265tr2-p235gh-p265gh-p355n-p355nh-p355nl1-p215nl-p265nl. See EN 10027-1 for other steel products. The national standard does not mention the European standard carbon steel materials, while the European standard covers carbon steel, alloy steel, stainless steel and other materials. The European standard is more comprehensive in the application range of European standard pipes.

2. 2 Comparison of standard pipe diameters between China and Europe

1) Nominal size comparison

DL/T 695 in DN series, gives two kinds of outer diameter size series, namely A series and B series. Series A is an international general series, namely the ISO series. The nominal diameter DN of Part 2 of EN 10253-2 comes from ENISO 6708; Series outer diameter from EN 10220, and seamless steel pipe

Seamless steel tubes for pressure purposes-technical delivery conditions part 2: non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10216-2 and welded steel pipes: welded steel pipes for pressure purposes-technical delivery conditions part 2: Electric welded non-alloy and alloy steel pipes with SPE Outside diameter series of certified elevated temperature properties en10217-2 are consistent. The nominal size and outer diameter series of European standards are completely consistent with the A series of national standards.

2) Comparison of the size range

DL/T 695 specifies the butt welded pipe fittings of the outer diameter control pipe size series DN15~DN1 200 and the butt welded pipe fittings of the inner diameter control pipe size series 146~1 067. The dimension series specified in Part 2 of EN 10253-2 is DN15-DN1200. The domestic standard DL/T 695 specifies the size of the outer diameter control pipe and inner diameter control pipe respectively. European standards do not distinguish between the size of outer diameter control pipe and the size range of inner diameter control pipe, and the diameter range is consistent with that of domestic control outer diameter pipe. The difference in size specification is due to the difference in actual processing capacity in different countries. When adopting different standards, attention should be paid to the regulation of their size range, and products that cannot be purchased should be avoided.

3. Comparison of types and pressure grades of standard pipe fittings between China and Europe

3. 1 Comparison of Standard Pipe Fittings between China and Europe

The domestic standard DL/T 695 does not distinguish between Class A and Class B according to whether the wall thickness of pipe fittings is the same as or increases with the wall thickness of connected straight sections. EN 10253-2 defines two types of pipe fittings: the wall thickness of the welded end of type A pipe fitting and the pipe fitting body is the same as that of the connecting straight pipe. Generally, their bearing capacity to internal pressure is smaller than that of straight pipes of the same size. The wall thickness of B-shaped pipe fittings is increased at the main body of the pipe fittings, so as to bear the same internal pressure as straight pipes of the same size. These two types of pipe fittings are used in the applications covered by EU Directive 2014/68/EU. Type a: butt welded pipe with reduced pressure coefficient x; The pressure coefficient x is defined as the pressure on the pipe fitting/the pressure on the straight pipe. For example, the pressure coefficient x of the welded elbow with a 2D bending radius of OD711×7.1 (wall thickness corrosion allowance 1 mm) is only 67%. Type b: butt welded pipe fittings used under full working pressure. According to this definition, the pressure piping system in the power industry generally adopts Class B pipe fittings. 3. 2 The pressure grade and strength are not specified in DL/T 695—2014 compared with the standard pressure grade of pipe fittings between China and Europe. In Part 2 of EN 10253-2, the wall thickness of Class B pipe fittings has set up 8 pressure grade series (the pressure values are not specifically defined in these 8 pressure grade series). Each series corresponds to the selected wall thickness of a straight pipe, and each pipe fitting has specific wall thickness parameters corresponding to the selected wall thickness of the straight pipe. For elbows, according to different bending radii, the minimum inner arc wall thickness Tint is defined. It can be seen that the strength (wall thickness) of pipe fittings of specific materials corresponding to specific pressure grades is not specified in the national standard and European standards. European standard only lists the wall thickness of pipe fittings under the recommended 8 pressure grade series but does not specifically define the pressure value. In addition, although the domestic standard DL/T 695—2014 does not specify the pressure grade and strength, in order to facilitate the selection, processing, manufacturing and procurement of steam-water pipes and fittings in thermal power plants, China Electric Power Design and Planning Association compiled Typical Design of Steam-water Pipe Parts and Components in Thermal Power Plants (GD 2016). "2016 Standard Pipe" is applicable to the design of metal steam-water pipe parts and components for units with ultra-supercritical parameters and below in thermal power plants, the design temperature of the pipe is not more than 628℃, and the capacity is not more than 1 000 MW. The manual of the 2016 Standard Pipe covers steel pipe varieties, elbows, reducers, tees, heads, flanges and assemblies, etc. This standard pipe has a feature, which sets the identification code of pipes or pipe fittings. The code has at least six units: the first unit is the name code; The second unit is the grade code, which is expressed by design pressure or design temperature. The third unit is material type; The fourth unit is the material code; The fifth unit is the type code; Unit 6 is the specification code. After identification and coding, the listing of pipes and pipe fittings is convenient for understanding the characteristics and materials of pipes and pipe fittings, and convenient for retrieval and standardized design. It is understood that due to intellectual property issues, there is no corresponding regulatory manual prepared by domestic trade associations in European standards. It is suggested that when the European standard is used, manufacturers capable of designing and manufacturing European standard pipe fittings should calculate the strength (strength design) according to the specific pressure grade, material and pipe fitting type of the pipe fittings according to the dimensions specified in these standards, so as to determine the specific wall thickness of the pipe fittings.

4. Comparison of Standard Dimensions, Wall Thickness and Form and Position Tolerance between Chinese and European Pipe Fittings

4. 1 Comparison of Standard Dimensional Tolerance between Chinese and European Pipe Fittings

DL/T 695—2014 lists the dimensional tolerances of various pipe fittings of outer diameter control pipe in Schedule E.1, which are specific values. The positive deviation of dimension is from 1.0 mm in DN 15 to 6.4mm in DN 1 200; The negative deviation is from 0.8 mm in DN 15 to 4.8 mm in DN1 200. Part 2 of EN 10253-2 defines that the dimensional deviation of pipe fittings is 1% or 0.5mm, whichever is greater, but the maximum is 5mm. In fact, the size deviation of European pipe fittings is slightly stricter than that of the national standard, which puts forward higher requirements for domestic pipe fittings manufacturers to produce European pipe fittings.

4. 2 Comparison of Wall Thickness Tolerance of Standard Welded End of Chinese and European Pipe Fittings

According to DL/T 695—2014, the maximum deviation of the wall thickness of the welding end is from 0.9 mm (DN≤65) to 5.6 mm (1 050≤DN≤1 200). Part 2 of EN 10253-2-2007 specifies the deviation of the wall thickness of welded end (for B-type pipe fittings): when the outer diameter is ≤610 mm, the deviation is-12.5%, +20% regardless of the wall thickness. When the outer diameter is > 610 mm, it can be divided into three categories:

1) Seamless pipe fittings, wall thickness-12.5%, +20%.

2) Weld pipe fittings with wall thickness ≤10 mm and deviation -0.35 mm, +20%.

3) Weld pipe fittings with wall thickness > 10mm, deviation -0.5 mm, +20%.

It can be seen from the above that for welded pipe fittings, the absolute value of the negative deviation of wall thickness required by the European standard is small, and there is no specific requirement in this aspect in the national standard. In addition, for seamless pipe fittings and welded pipe fittings, the positive deviation of wall thickness in European standards is 20%, and there is no specific requirement in the national standard. It can be seen that, in general, the European standard has a narrower control range for wall thickness tolerance.

4. 3 Comparison of Standard Form and Position Tolerances between Chinese and European Pipe Fittings

According to DL/T 695—2014, when the nominal size is 15 - 100, the form and position tolerance x = 1 mm; X = 2 mm at 25 - 200; X = 3 mm at 25 - 400; X = 4 mm at 40 - 600; X=5 mm at 60 - 1 200. Part 2 of EN 10253-2 stipulates that the geometric tolerance X is ≤ 1% or 1 mm of the outside diameter of the measuring point, whichever is greater. When the European standard is used for large diameter pipe fittings, that is, DN>500, the form and position deviation is lower than that required by a national standard. When the diameter of DN<500, the deviation of form and position is consistent with the national standard, which is 1% of the outer diameter. The overall European standard is stricter than the national standard in form and position deviation. By comparing the size, wall thickness, shape and position deviation of Chinese and European standard pipe fittings, the allowable deviation range of European standard is narrower than that of national standard, and the overall requirements are stricter than that of national standard. The main reason is that the European manufacturing process is more sophisticated than that in China. If domestic pipe fittings factories need to manufacture European standard pipe fittings, they need to improve their manufacturing level.

5. Comparison of end groove forms of standard pipe fittings between China and Europe

DL/T 695 stipulates that when the nominal wall thickness of carbon steel and ferritic alloy steel is 5 mm≤tn≤22 mm and the nominal wall thickness of austenitic stainless steel is 3mm≤tn≤22 mm, a V-shaped groove shall be adopted; Nominal wall thickness ≥22mm, with double V-shaped groove; The rest is not specified. The bevel angle of the end of the V-groove is 37.5 2.5. The bottom surface is 1.5mm 1.0mm.. Part 2 of EN 10253-2 stipulates: According to the manufacturer's choice, for the specified wall thickness of less than 3 mm, both ends can be cut into squares or slightly chamfered. If the wall thickness is between 3 and 3-22 mm, the oblique angle of its end should be 30 5, and its bottom should be 1.6 mm±0.8 mm If the wall thickness exceeds 22 mm, it should be approved by the purchaser. By comparison, the Sino-European pipe fitting standards are almost identical in the end groove form and wall thickness grading of pipe fittings. The only difference is that the angle of bevel angle and the size of the bottom surface are slightly different, which depends on the processing and manufacturing characteristics of different countries, regardless of the advantages and disadvantages.

6. Comparison of Minimum Wall Thickness for Standard Calculation of Pipe Fittings between China and Europe

Comparative example: seamless elbow nozzle OD168.3×4.5, material P265GH, design pressure: 1.03 MPa (g), design temperature: 379℃, allowable stress of material: 91.29 MPa. For the sake of comparison, the bending radius is 1.5 times the outer diameter, regardless of wall thickness deviation and wear prediction. The strength design of domestic standard DL/T 695 pipe fittings comes from the steam code DL/T 5054—2016, and the formula for calculating the minimum wall thickness of the elbow is as follows:

Type:

P —— design pressure [MPa (g)];

D0 —— the outer diameter of the pipe;

[σ] t —— the allowable stress at the design temperature (MPa);

η-correction coefficient of allowable stress;

I-correction coefficient of elbow wall thickness;

Y-correction coefficient.

Sm=1.03×168.3/2× (91.29+0.4×1.03)=0.95 mm; The strength design of pipe fittings in part 2 of European standard EN 10253 comes from European standard EN 13480-3, and the minimum wall thickness formula of elbow inner arc is as follows:

When Do/Di≤1.7;

Type:

E —— minimum wall thickness of straight pipe (mm);

Pc-design pressure [MPa (g)];

Do —— the outer diameter of the pipe;

F —— allowable stress at design temperature (MPa);

Z —— weld coefficient;

R —— bending radius of the elbow (mm).

eint=1.03×168.3(/ 2×91.29×1+1.03) × (1.5-0.25)/(1.5-0.5)=1.18 mm; After comparison, the wall thickness deviation and wear allowance are not considered in the strength calculation standards of pipe fittings in China and Europe, and the European standard formula of the minimum wall thickness of elbow will be conservative.

7. Other Comparison of China-Europe Pipe Fitting Standards

7. 1 Comparison of Flow Area of Pipe Fittings between China and Europe

According to DL/T 695, the minimum inner diameter of the elbow and tee should ensure that the flow area is equal to that of the nozzle, and the flow area should not be less than 95% of that of the nozzle. Part 2 of EN 10253-2 stipulates that in order to ensure the normal flow of fluid through the pipe fittings, the inner diameter of any part of the pipe fittings (not applicable to the head) should be greater than 80% of the inner diameter ID. The national standard has higher requirements on the flow area than the European standard and is better in controlling the flow resistance of the medium.

7. 2 Comparison of Bend Radius between China and Europe

According to DL/T 695, it can be divided into a long radius (equivalent to 1.5 times the outer diameter) and a short radius elbow (equivalent to 1 times the outer diameter). Part 2 of EN 10253 stipulates that it can be divided into 2D (equivalent to 1.5 times the outer diameter), 3D (equivalent to 1.5 times the outer diameter) and 5D series (equivalent to 2.5 times the outer diameter). The expression of the series of bending radii in European standards is different from that in China, which is twice the bending radius in China. At the same time, the series of the bending radii are more abundant.

7. 3 Comparison of internal pressure instructions between Chinese and European pipe fittings

There is no administrative instruction for pressure equipment in domestic standards. Part 2 of EN 10253-2 makes it clear that the pressure equipment directive (2014/68/EU) stipulates that the design of sufficient strength should be based on the calculation method or limited to the experimental method. The resistance of pipe fittings conforming to this European standard to internal pressure should be based on EN 13480-3. It is the ultimate responsibility of the pressure equipment manufacturer to select the appropriate pipe fittings (material and thickness). Only products entering the European market need to comply with the EU directive, and pressure equipment just needs to comply with the PED directive (2014/68/EU). In addition, the last annex of Part 2 of EN 10253-2 also has an explanatory table on the compliance of this standard with the provisions of the European Union directive PED (2014/68/EU). This is a significant difference between European standards and domestic standards.

Conclusion

China's belt and road initiative policy urges domestic electric power design businesses to go abroad, to a wider overseas market, and to compete with large foreign engineering consulting companies for international projects. In the past, most overseas projects were in Southeast Asian countries or Middle Eastern countries. Now, our business has expanded to Europe. In addition to practicing the basic skills of national standards or American standards, we also need to be familiar with the local European design standards and habits. Similarly, domestic pipeline and pipe fittings manufacturers also need to study the European market norms simultaneously and jointly go out to sea to win the vast continental European market. This paper introduces the domestic pipe fitting standards and the European pipe fitting standards compared with them and compares the Chinese and European pipe fitting standards from many angles. The following conclusions are obtained:

1) European standards are used in a wider range of industries.

2) European standard is more comprehensive in the application range of pipes. The nominal size and outer diameter series of European standards are completely consistent with the A series of national standards. The range of European standard pipe diameter is consistent with the size of domestic controlled outer diameter pipe.

3) European standard EN 10253-2 distinguishes Class A and Class B according to whether the wall thickness of pipe fittings is the same as or increases with that of connected straight sections. The power pressure pipeline system in the industry adopts Class B pipe fittings, but there is no Class A classification. There is no regulatory manual prepared by domestic trade associations in European standards. It is suggested that when European standard is used, manufacturers capable of designing and manufacturing European standard pipe fittings should design according to the specific pressure grade, material and pipe fitting type of pipe fittings and draw the manufacturing drawings of European standard pipe fittings.

4) By comparing the size, welding end wall thickness and form deviation of standard pipe fittings between China and Europe, the European standard is stricter than the national standard. The main reason is that the European manufacturing process is more sophisticated than that in China. If domestic pipe fittings factories need to manufacture European standard pipe fittings, they need to improve their manufacturing level.

5) By comparison, the bevel angle and bottom dimension of the end groove of pipe fittings between China and Europe are slightly different, which depends on the manufacturing characteristics of different countries and regions.

6) Through the comparison of calculation examples, the European pipe strength calculation standard will be conservative and safer.

7) European pipe fittings have their own special places in terms of flow area and bend radius. In addition, all pipe fittings entering the European market need to comply with the PED Directive (2014/68/EU). Part 2 of EN10253-2 has a cross-reference on the compliance of this standard with the EU directive PED (2014/68/EU). This is a special point for domestic pipe fittings factories to enter the European market. Besides meeting the relevant European design, manufacturing and inspection standards, it also needs to comply with PED administrative instructions. The above conclusion points out the similarities and differences between Chinese and European pipe fitting standards, which have certain reference significance for domestic electric power design institutes and domestic pipe fitting manufacturers to understand.